As India’s sports infrastructure grows, the demand for high-performance, durable and visually appealing acrylic flooring is also increasing. Whether you are building a new tennis court flooring, a multi-sport area or renovating an old basketball court surface, synthetic acrylic flooring is the top choice due to its durability, versatility and cost-effectiveness.

But a long-lasting high-performance synthetic court requires more than just good quality materials. The foundation of a good court lies in proper pre-installation planning. This checklist helps ensure every detail is covered before a single drop of acrylic floor paint is applied.

1. Site Assessment and Ground Evaluation

Before installation of a sports court, a thorough site evaluation is necessary. This includes checking the site’s drainage, accessibility and existing court base conditions.

Knowing the local climate, average humidity and surrounding structures will help in choosing the right synthetic flooring materials and scheduling the application at the right time.

Site inspection should also identify obstacles like trees, poles or nearby buildings that may affect the court’s layout or long term maintenance. For permanent installations, site surveys should confirm boundary limits and utility lines.

2. Standard Court Dimensions and Layout

Each sport has its own dimension standards and these must be checked during court design and marking. Multi-purpose courts require good planning to accommodate multiple sport court dimensions without overcrowding.

Verify the required standard sport court size as per ITF, BWF or FIBA guidelines depending on the sport. Multi sport court dimensions should allow for player movement, safety zones and line marking separation.

Plan the multi sport court design early to get better sports court material estimation and smooth installation. Courts built without proper dimension planning will have uneven play and poor user experience.

3. Sub-Base Selection and Groundwork Preparation

The most critical element in the longevity of synthetic acrylic flooring is the stability and quality of the sub-base. The sub-base should be concrete or asphalt with a minimum slope of 1%.

For new sports court constructions, the concrete base should cure for at least 28 days and be free of oil, grease or curing compounds. Cracks or imperfections in court should be filled with appropriate patching compounds compatible with acrylic systems.

An uneven or un compacted base will lead to premature wear, delamination or water pooling on the acrylic floor surface. Ensure the entire synthetic ground is pressure washed and dust free before applying any coating.

4. Synthetic Flooring Materials

Not all synthetic flooring materials are manufactured equal. Ensure your vendor provides a complete system including primer, resurfacer, cushion coats (if needed), color coatings and line marking paint.

A good synthetic acrylic sports flooring manufacturer in India like Top Flooring offers multilayer systems for extreme weather conditions, sport specific performance and user expectations. The material quality impacts the surface’s durability, UV resistance and shock absorption.

5. Acrylic Coating System Selection

A proper sport court coating system has multiple layers that serve different purposes. Each layer contributes to the system’s longevity, performance and appearance.

Start with a concrete primer to enhance adhesion in the sports court, then apply an acrylic resurfacer to level and seal the surface. Next, apply one or more cushion coats if the court needs more comfort and shock absorption.

Finish with pigmented sports court paint and clear acrylic floor finish to protect the surface from UV rays, dust and wear. The acrylic floor coatings you choose should meet international sports flooring standards.

6. Moisture Testing and Surface Readiness

Moisture is one of the biggest threats to synthetic flooring integrity. A concrete base should have moisture content below 5% to avoid delamination of the acrylic layers.

Use a calcium chloride or Tramex moisture meter to test the surface. Ensure there is no efflorescence (white powdery residue) or water seepage that may affect bonding.

This is very important for older courts that are being resurfaced. If moisture is found, it has to be resolved before proceeding with the installation of acrylic floor coloring or color coats.

7. Favorable Climate and Environment

Acrylic flooring systems need favorable weather for installation. Plan your project during dry seasons and monitor the forecast to avoid rain during or after coating applications.

The ideal temperature range for applying acrylic floor coatings is between 15°C to 35°C. Sports court coatings should not be applied in high humidity, direct sunlight during peak hours, or when there is a lot of dust.

Bad weather like rain or extreme heat can cause moisture in the sports court, alter drying times, or result in uneven finishes. In India, the best time to install a court is between October and March, when the weather is normal and more stable.

8. Tool and Equipment

Proper tools and equipment ensures consistent application and adherence to sports court system specifications. Don’t depend on manual labor for leveling or coating.

Industrial squeegees, line marking tools, mechanical grinders, pressure washers, and humidity meters are all necessary equipment. For acrylic floor paint and resurfacing, specialized roller systems and mixers are required.

Before work starts, make sure all of the equipment is sanitized, adjusted, and tested. Inappropriate line marks, uneven thickness, and material waste might result from using the wrong equipment.

9. Color Scheme and Customization Planning

Selecting the ideal sports court colors involves considerations of player performance, contrast, and visibility in addition to the court’s aesthetics. Additionally, the acrylic floor paint of choice needs to be anti-glare and UV resistant.

Popular combinations include purple and gray for pickleball court flooring, red and yellow for basketball, and blue inner courts with green outer zones for tennis. The acrylic floor finish can also include zone coloring, custom branding, or logos.

Work with Top Flooring, the best manufacturers that offer multiple acrylic flooring color options which fit your facility’s theme or sports usage requirements.

10. Labor and Contractor Selection

Installation of sports courts should only be done by trained applicators or recommended sports flooring contractors. Check the team’s experience with synthetic acrylic flooring projects and if they have worked with your chosen product line.

Labor planning includes team responsibilities, material handling, mixing supervision, application control and curing supervision. Ask your sports flooring company or manufacturer to provide on-site support or training if you’re using in-house labor for the project.

11. Timeline and Logistics Planning

Time management is important for sports court project success. Delays can expose uncured layers to environmental damage or force re-application of coatings.

Create a realistic schedule that includes base curing, layer-wise drying times and line marking. Consider buffer days for weather related interruptions.

Coordinate with logistics teams so that outdoor sport court material like coatings, resins and equipment reaches on time and is stored properly in dry conditions.

12. Budget and Cost Evaluation

Proper budgeting avoids mid-project compromises. The acrylic flooring cost should include materials, labor, site prep, and transportation contingencies.

Understand the pricing structure for synthetic flooring materials, especially if you’re adding cushion coats or premium finishes. Get quotations from multiple sports flooring manufacturers in India to compare pricing and inclusions.

Don’t forget recurring maintenance costs like surface cleaning, repainting or topcoat re-application every few years.

13. Quality Assurance Protocols

Establish a step by step quality check for each phase of installation of the sports court. Use straight edges to check leveling, moisture meters for curing and thickness gauges to check layer application.

Check the base after priming, and cushion application before applying the acrylic floor finish. Ensure line markings follow regulation standards of the sports court.

All sports flooring materials should be batch labeled and consumption rates should match manufacturer guidelines. Document each stage to avoid future disputes.

14. Documentation and Compliance

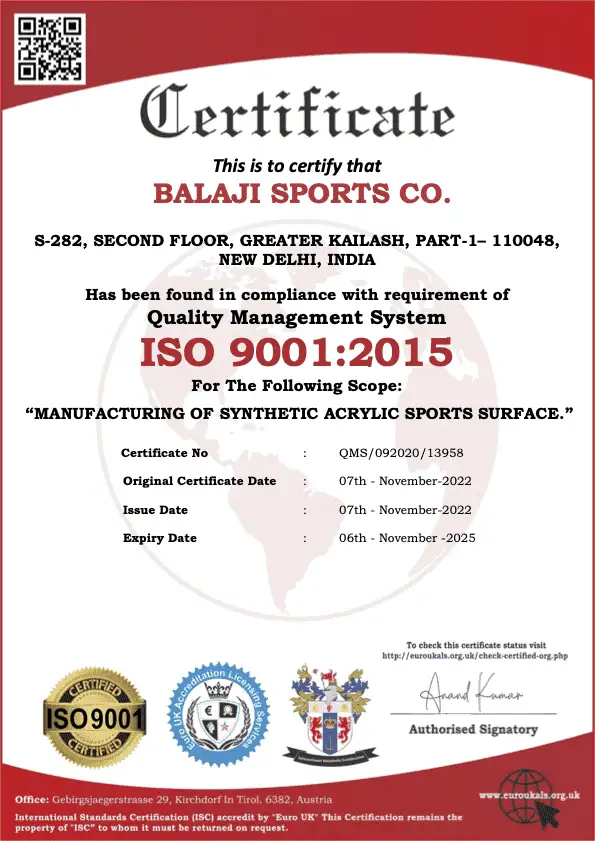

Keep a record of all material data sheets, application guides, warranties and installation procedures provided by your synthetic acrylic sports flooring manufacturer in India.

For government or institutional projects, compliance documents may be required to confirm ITF/BWF/FIBA surface classification.Keep photographs, test reports and invoices organized. This will help in future resurfacing, warranty claims or expansion work.

15. Safety and After Installation Planning

While installation of sports flooring is in progress, ensure safety protocols are in place. Keep unnecessary staff off the court, store chemicals safely and with necessary ventilation.

After completion of the sports court, barricade the floor court for at least 48 hours. Do not allow player access until full curing is done and the surface is inspected. Plan your after installation care with regular cleaning, surface inspection and recoating every 3-5 years depending on usage.

Conclusion

Installing a synthetic acrylic flooring system is a technical process that starts long before the first layer of paint is applied. Skipping any part of the pre-installation process can lead to early failures, costly repairs and safety issues for players. By following this checklist, your court—whether it’s for pickleball, tennis or a multipurpose court will perform at its best.

Contact Top Flooring now for best sports flooring materials.

Frequently Asked Questions

Acrylic flooring is used for sports courts like tennis, basketball and multi sport areas because of its durability, weather resistance and vibrant court paint options.

Look for a company like Top Flooring with experience, high quality synthetic flooring systems, technical support and product certifications.

Yes, acrylic floor coatings are available in custom colors, logos and anti-glare finishes to match any court theme.

Yes, only experienced sports flooring contractors or certified applicators should install acrylic flooring.

Plan logistics early, store materials in dry conditions, schedule during dry seasons and include buffer days for curing and weather issues.