Pickleball, one of the fastest growing sports globally has found a strong following across Indian schools, clubs and housing societies. With its compact layout, exciting rallies and family friendly appeal many communities are now investing in pickleball court construction. But one common question always asked: what is the actual pickleball court construction cost and how can it be built affordably without compromising quality?

This detailed guide helps in understanding pickleball court flooring, including materials, systems and smart construction methods to achieve low cost outdoor pickleball court flooring that meets professional play standards. Whether you are building a home pickleball court or multiple courts for a club or academy. Understanding the cost of pickleball court construction and selecting the right materials will ensure durability, comfort and aesthetics for years.

What is Pickleball Court Flooring and Why is it Important?

A pickleball court floor is not just a playing surface it is the foundation that defines the game’s overall experience, performance and overall lifespan. Every rally, serve and step taken on the court, depends on how well the flooring has been engineered. An ideal pickleball court surface balances grip, bounce and resilience. So players can enjoy consistent performance without risking injury or facing frequent maintenance issues.

The flooring system plays a crucial role in controlling ball response and player comfort. A surface that is too hard can cause joint stress, while one that is too soft may absorb too much energy and slow down gameplay. This is why professional pickleball court flooring is designed with precise material composition that maintains elasticity, speed and traction for both recreational and competitive play.

In India’s diverse weather conditions scorching heat, monsoon rains and extended dry spells flooring durability becomes even more critical. Modern pickleball court surface materials are designed to withstand ultraviolet exposure, temperature changes and moisture absorption without cracking, peeling or fading. This type of performance driven engineering ensures the court maintains its quality year after year even with heavy daily usage.

Why Synthetic Acrylic is the Best Low Cost Pickleball Flooring Option?

When it comes to pickleball court surface options, builders often compare materials like concrete paint, tiles and polyurethane (PU). But acrylic pickleball court material stands out as the most economical and professional grade choice.

Benefits of Synthetic Acrylic Flooring:

- Low Cost: Less material cost and minimum machinery required compared to PU or modular tile systems.

- Long Lasting: Synthetic acrylic flooring can last 10 years with regular maintenance.

- Weather Proof: UV rays, rain and temperature fluctuations are no match for acrylic coatings in Indian outdoor conditions.

- Professional Bounce: Consistent ball response and player comfort for beginners and athletes.

- Easy Maintenance: Simple cleaning and recoating makes the pickleball court look fresh without major repairs.

In short, acrylic pickleball court material gives you more with less investment.

Pickleball Court Construction Process

Building a pickleball court is a science that involves multiple precision layers working together to ensure long term performance, durability and player safety. The pickleball court construction process followed by professional pickleball court builders like Top Flooring are as follows.

Step 1: Base Preparation

The base is the structural backbone of the entire pickleball court, designed to take load, drainage and surface stability. It can be made of asphalt or concrete depending on local conditions and budget.

- Asphalt Base: Preferred for outdoor courts due to its flexibility, smooth texture and resistance to minor ground movements.

- Concrete Base: It offers durability, low maintenance and long term structural integrity, ideal for permanent pickleball court installations. And a slope of about 1:100 is maintained to allow water drainage and prevent pooling or algae buildup.

Step 2: Application of Acrylic Layers

Once the base is fully cured and moisture tested. An acrylic resurfacer coat is applied to seal pores and create a smooth surface. Then cushion layers are applied to absorb impact and color coats to provide grip, visual appeal and uniform ball response.

Step 3: Line Marking & Finishing

After the surface is cured, professional pickleball court builders use ITF standard marking paints to apply court lines for competitive accuracy. Line markings are done with non-fading, high adhesion paints for excellent visibility and premium finish.

Step 4: Quality Inspection

Before handover of the project, a detailed inspection is done to verify bounce uniformity, grip level and surface evenness. Special attention is given to slope accuracy, coating thickness and edge detailing to ensure tournament level play even in low cost pickleball court construction projects.

Pickleball Court Construction Cost: Breakdown

Understanding pickleball court construction costs helps in budgeting effectively and avoiding hidden costs. The cost depends on materials, base type, labor and location.

Below is the approximate cost breakdown for pickleball court construction in India:

| Component | Estimated Cost (INR) | Remarks |

| Base Preparation (Concrete/Asphalt) | ₹80 – ₹130 per sq. ft. | Includes leveling and curing |

| Acrylic System (5–8 Layers) | ₹70 – ₹120 per sq. ft. | Includes resurfacer, cushion, color coats |

| Court Markings & Accessories | ₹15 – ₹25 per sq. ft. | Includes lines, nets, and finishing |

| Total Estimated Cost | ₹1,65,000 – ₹2,20,000 (per court) | Depending on quality and layers |

The above idea of the cost of pickleball court construction for a standard 30 ft × 60 ft court. Professional pickleball court construction companies like Top Flooring offer customized packages for academies, institutions and residential projects.

Factors Affecting Pickleball Court Construction Cost

Several factors can impact the pickleball court construction cost. So smart planning is key to long term savings and performance consistency.

Base Material and Site Condition: The base plays a major role in cost, uneven terrain or soft soil needs extra leveling or filling, which increases pickleball flooring cost. Though slightly more expensive, a well laid concrete base ensures long term stability and minimum future maintenance.

Layer System: Number of layers determines comfort and durability. A 5 layer system is good for budget builds, while an 8 layer cushion system is for high level play.

Material Brand: Choosing reputed, lab tested pickleball court materials ensures uniform coating thickness, UV resistance and durability. Which resulted in lower maintenance cost over time and better overall performance.

Location and Labor: Project location impacts logistics. Remote areas have higher transportation and labor cost. While urban areas have easier access to materials and skilled technicians.

Add-ons: Additions like LED lighting, fencing or advanced drainage enhance functionality but can add ₹30,000-₹70,000 based on specifications and quality.

With proper planning, accurate base preparation and smart selection of acrylic materials, professional grade pickleball court flooring can be achieved even on modest budgets.

How to Build an Outdoor Pickleball Court?

Outdoor pickleball courts are exposed to sun, rain and dust 24/7 which can wear down poor quality surfaces. So outdoor pickleball court flooring must combine durability, weather resistance and low maintenance for long term performance.

Why Acrylic Coatings are Best for Outdoor Court?

- High UV Resistance Prevents Fading and Peeling: Acrylic coatings have UV stable pigments that resist the harsh Indian sun, keeping colors vibrant and preventing surface cracking or peeling even after years of outdoor exposure.

- Quick Drying Time Reduces Installation Delays: Acrylic based systems dry fast, allowing contractors to apply multiple layers quickly and complete installation faster even in fluctuating weather conditions.

- Smooth but Non-Slip Texture for All Season Safety: The micro textured surface of acrylic flooring provides excellent grip in wet or dry conditions. And reduces slip hazards and maintains smooth ball response and player comfort.

- Works on New and Resurfaced Bases: Acrylic systems bond well with concrete and asphalt bases. So it can be used for new pickleball court construction and resurfacing of older pickleball courts without any structural changes.

Also acrylic coatings are available in various color options like blue-green, terracotta, red and grey so facilities can customize court look without increasing the cost. For coastal or humid areas, it’s recommended to apply moisture-barrier primer underneath the acrylic layers to prevent bubbling, vapor transmission and long term surface damage.

Comparing Pickleball Court Surface Options

To make an informed decision, here’s how common pickleball court surface options compare:

| Surface Type | Average Cost (₹/sq.ft.) | Lifespan | Maintenance | Remarks |

| Acrylic System | 70–120 | 10–12 years | Low | Ideal balance of cost & performance |

| PU Flooring | 180–250 | 10–15 years | Moderate | High cost; indoor preferred |

| Modular Tiles | 250–350 | 10–15 years | Low | Good drainage but expensive |

| Cement Paint | 30–50 | 2–3 years | High | Cheapest but short-lived |

Clearly synthetic acrylic pickleball court flooring is the best balance of affordability, durability and quality for professional and recreational courts.

How to Build a Home Pickleball Court?

The trend of building a home pickleball court is growing fast among fitness enthusiasts, families and residential communities. It gives daily access to recreation and enhances property value and aesthetics.

Home Installations:

- Space: A standard pickleball court requires a 30×60 ft playing area with an extra 10 ft safety margin around it for free movement. Proper spacing ensures safety, comfort and international standards.

- Base: Use a well-cured concrete or asphalt base with a gentle slope for water drainage. The base quality and stability determines how long the surface will last without cracks or unevenness.

- Material: Go for acrylic pickleball court material that gives a professional finish and weather resistance at an affordable price. Synthetic acrylic coatings give a smooth texture, excellent ball bounce and vibrant appearance.

- Drainage: Add side slopes or perimeter channels to guide rainwater away from the surface efficiently. Proper drainage prevents puddles, algae growth and surface damage during monsoons.

- Lighting: Install 200–300 lux LED floodlights symmetrically to ensure even lighting during evening play. Energy efficient lighting allows extended play hours with minimal power consumption.

Professional pickleball court builders near me, like Top Flooring’s certified partners, offer end to end solutions from surface preparation to finishing accessories to give you a home court that’s durable, safe and built to global standards.

Choosing the Right Pickleball Court Builders

A successful court project depends not only on materials but also on skilled pickleball court builders. The best contractors combine engineering precision, technical expertise and proven experience in sports flooring systems to give lasting performance and safety.

Qualities of Good Pickleball Court Builders:

- Experience with synthetic acrylic flooring systems: Builders with hands-on experience in acrylic sports flooring know layer composition, curing times and surface properties required for consistent bounce and grip.

- Knowledge of slope design and curing processes: Correct slope and curing ensures effective drainage, prevents surface cracks and enhances long term court durability in outdoor environments.

- ITF rated materials and methods: Certified materials tested for friction, pace and resilience to ensure the court meets international play standards and safety guidelines.

- Surface uniformity and precision: Attention to coating thickness, texture and line accuracy to give a professional finish that supports fair play and aesthetics.

- End to end construction: Reputed builders manage every stage—from base preparation and primer application to topcoat and marking to give seamless project delivery with technical accountability.

Working with pickleball court construction companies like Top Flooring means expert execution, consistent quality and a surface built for professional play.

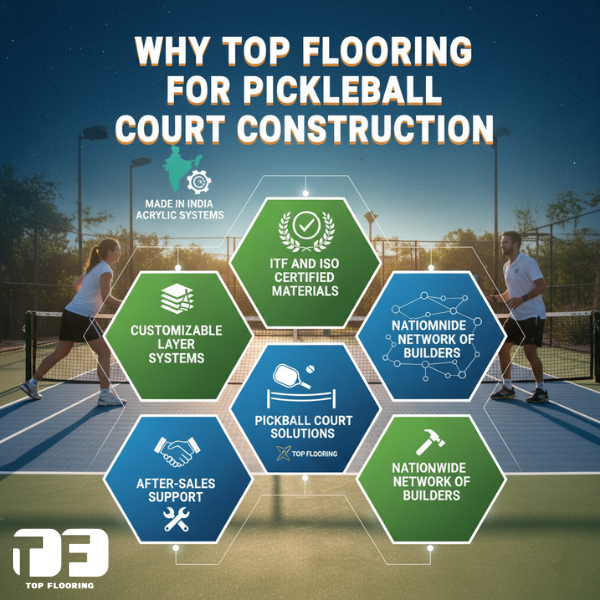

Why Top Flooring for Pickleball Court Construction?

Top Flooring is one of the most trusted names in pickleball court flooring in India, providing complete solutions from high quality material supply to expert on-site installation for various sports facilities. Every system is designed to balance performance, durability and affordability.

- Made in India Acrylic Systems: Each product is formulated and tested in India to perform under India’s extreme heat, monsoon moisture and UV exposure for long term surface stability and grip consistency.

- ITF and ISO Certified Materials: All coatings and resins are internationally certified for professional grade bounce, surface pace and safety as per global sporting standards.

- Customizable Layer Systems: Available in 5 layer, 6 layer and 8 layer configurations, clients can choose systems as per their budget, play requirements and court usage.

- Nationwide Network of Builders: Top Flooring works with certified installers and contractors across India for standardized construction and faster project execution in every region.

- After-Sales Support: From periodic maintenance advice to resurfacing and recoating guidance, clients get continuous technical support for sustained court performance and aesthetics.

Whether for institutional projects, residential societies or private properties, Top Flooring offers innovative, cost effective and reliable pickleball court flooring systems for long lasting play and low maintenance.

Smart Ways to Reduce Pickleball Court Construction Cost

Building a pickleball court does not always need a big budget. With smart planning and material selection you can save pickleball court construction costs without compromising on performance or longevity.

Practical Cost Saving Tips:

- Use standard color coats (blue/green) instead of custom tints, standard shades are pre-formulated, widely available and cost less to produce. Hence reduce overall pickleball court material cost.

- Choose 5 layer acrylic system for recreational courts this setup offers excellent playability and durability for casual and training use without the added expense of premium cushion systems.

- Buying materials directly from manufacturers to avoid markups, buying directly ensures genuine quality, bulk pricing benefits and consistent supply at lower cost.

- Ensure proper sub-base to avoid future pickleball court repairs. A well prepared base prevents cracks, uneven surfaces and drainage issues which can lead to costly resurfacing later.

- Go for multi-purpose layouts combining pickleball and badminton zones shared flooring systems maximize space utilization and save on construction and maintenance cost for multiple sports. Smartly!

Environmental and Economical Benefits of Acrylic Flooring

Apart from being affordable acrylic pickleball court material has environmental and long term financial benefits:

- Low VOC emissions: Eco friendly non toxic coatings for a safer playing environment and meets global green standards.

- Longer life: Durable acrylic layers minimizes resurfacing needs, reduces material waste and long term maintenance cost.

- Energy efficient installation: Fast drying formulations reduce electricity and water consumption making the process eco conscious and cost effective.

So synthetic acrylic pickleball court flooring supports sustainability and performance and value.

Conclusion

Pickleball’s growing popularity has created a new wave of construction demand — from academies to apartment complexes and backyard courts. But building a good court doesn’t have to burn a hole in your pocket. By choosing synthetic acrylic pickleball court flooring project owners can get the perfect balance of cost, performance and durability. With professional grade materials, expert application and ITF standard finishes, affordable courts can perform like professional ones.

Top Flooring is redefining affordable sports infrastructure by offering tested, eco-friendly and long lasting systems for pickleball court construction in India. From pickleball court material supply to pickleball court installation the brand ensures value for money that lasts.

Frequently Asked Questions

The average pickleball court construction cost is around ₹1.8 – ₹2.2 lakh per court, depending on layers and materials used.

Synthetic acrylic flooring offers the best balance of durability, bounce, and affordability.

Yes, you can build a pickleball court at home with about 30×60 ft of space and a concrete or asphalt base, you can build a home court.

Properly installed pickleball flooring lasts 4–6 years with regular maintenance.

According to many athletes, sports enthusiast the major pickleball court builders in India are – Top Flooring, AQS, SLT Sports, and Pacecourt are the trusted suppliers and installers of acrylic pickleball court systems.