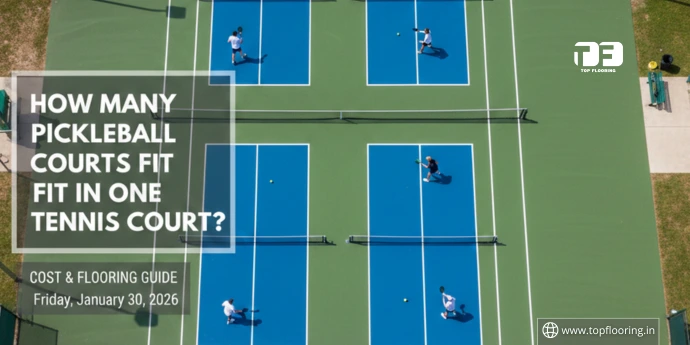

Pickleball is one of the fastest-growing sports worldwide, and India is quickly catching up. From residential communities and schools to clubs and resorts, demand for professionally built courts is rising. However, successful pickleball court construction requires proper planning — from understanding official pickleball dimensions to selecting the right pickleball court flooring material and hiring an experienced pickleball builder. This guide covers everything needed to build a durable, professional-grade pickleball court.

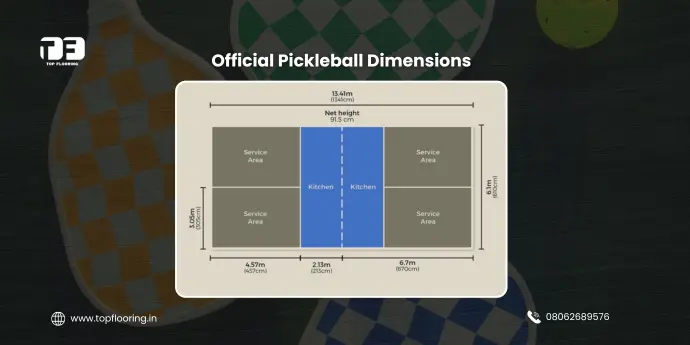

Official Pickleball Dimensions Explained

Before starting construction, understanding standard dimensions is critical. Pickleball follows internationally recognized court measurements similar across recreational and professional setups.

Standard Pickleball Court Dimensions

- Court Length: 44 feet

- Court Width: 20 feet

- Total Playing Area: 880 sq. ft.

- Non-Volley Zone (Kitchen): 7 feet from the net on both sides

- Service Area: Divided into right and left sections

Recommended Total Space (Including Run-Off Area)

For safe play and tournaments:

- Minimum Area: 30 ft × 60 ft

- Preferred Tournament Area: 34 ft × 64 ft

Providing adequate run-off space ensures player safety and compliance with professional standards.

Net Specifications

- Net Height at Center: 34 inches

- Net Height at Posts: 36 inches

Accurate measurement and marking are essential for bounce consistency and competitive play standards.

Choosing the Right Pickleball Court Flooring Material

The performance of a pickleball court heavily depends on the pickleball court flooring material selected. Flooring impacts ball bounce, player comfort, durability, and maintenance cost.

1. Synthetic Acrylic Flooring (Most Recommended)

Synthetic acrylic flooring is widely preferred for outdoor pickleball court construction.

Advantages:

- Uniform ball bounce

- UV resistant and weatherproof

- Slip-resistant texture

- Low maintenance

- Cost-effective long-term

This multi-layer coating system is applied over a concrete or asphalt base and provides excellent durability in Indian climatic conditions.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

2. Concrete Base with Acrylic Coating

A reinforced concrete base ensures structural strength. Acrylic layers on top enhance playability and aesthetics.

3. Modular PP Tiles (Alternative Option)

While modular tiles are portable and quick to install, they may not provide the same professional-level bounce and long-term durability as acrylic systems.

For long-term projects, synthetic acrylic flooring remains the most reliable pickleball court flooring solution.

Essential Materials Required for Pickleball Court Construction

Professional pickleball builders use high-quality materials to ensure durability and safety.

Base Construction Materials

- Compacted sub-base (WMM or stone aggregate)

- Reinforced concrete or asphalt layer

- Proper drainage system

Surface Materials

- Acrylic primer

- Cushion layers (optional for comfort)

- Acrylic color coating

- Line marking paint (white textured paint)

Accessories

- Net posts (galvanized steel)

- Pickleball net

- Fencing (optional but recommended)

- Lighting poles for night play

Using premium materials ensures the court lasts 8–12 years with minimal resurfacing.

Step-by-Step Pickleball Court Construction Process

Understanding the construction stages helps in monitoring quality and timeline.

1. Site Inspection & Planning

Soil testing, drainage planning, and layout marking are conducted.

2. Base Preparation

Excavation and compaction of the sub-base layer for stability.

3. Concrete or Asphalt Installation

A smooth, crack-resistant base is poured and cured.

4. Surface Coating Application

Primer → Cushion coat → Acrylic color layers → Line marking.

5. Net & Accessories Installation

Posts, net system, fencing, and lighting are installed.

The entire construction process typically takes 3–5 weeks, depending on weather and project size.

How to Choose the Right Pickleball Builder

Selecting a professional pickleball builder determines the long-term success of the project.

Key Qualities to Look For:

- Experience in synthetic sports flooring

- Knowledge of official pickleball dimensions

- Use of high-quality acrylic materials

- Proper drainage planning

- Transparent cost breakdown

- After-sales maintenance support

An experienced pickleball builder ensures proper slope (usually 1%) for water drainage and long-term surface durability.

Cost of Pickleball Court Construction in India

Construction cost depends on location, base condition, material quality, and additional facilities.

Approximate Cost Factors:

- Base construction cost

- Acrylic flooring material cost

- Labor charges

- Fencing & lighting

- Branding or logo customization

On average, a standard outdoor pickleball court may cost between ₹6 lakh to ₹12 lakh depending on specifications. Investing in quality materials reduces maintenance costs over time.

Pickleball Court Construction Cost in India (Detailed Breakdown)

Cost varies based on location, soil condition, material quality, and additional features.

Below is a realistic cost estimate for a standard outdoor pickleball court (India).

Base Construction Cost

| Component | Approximate Cost |

| Excavation & Sub-base | ₹80 – ₹120 per sq. ft. |

| PCC/RCC Concrete Base | ₹150 – ₹250 per sq. ft. |

For a 30 × 60 ft area (1,800 sq. ft.), base cost may range: ₹3.5 lakh – ₹5 lakh

Pickleball Court Flooring Cost (Acrylic System)

| Component | Approximate Cost |

| Acrylic Surface System | ₹120 – ₹180 per sq. ft. |

For 1,800 sq. ft.: ₹2.1 lakh – ₹3.2 lakh

Additional Cost Elements

| Feature | Estimated Cost |

| Net & Posts | ₹25,000 – ₹45,000 |

| Fencing (10–12 ft height) | ₹1.5 – ₹2.5 lakh |

| LED Sports Lighting | ₹2 – ₹4 lakh |

| Branding / Logos | ₹20,000 –₹60,000 |

Indoor vs Outdoor Pickleball Court Construction

Outdoor Courts

- Require UV-resistant pickleball court flooring

- Proper slope for drainage

- Weather-resistant coatings

Indoor Courts

- No drainage slope required

- Controlled environment

- Can use cushioned acrylic systems for comfort

Outdoor courts are more common in India due to space availability and lower infrastructure costs.

Why Synthetic Acrylic Flooring is Ideal for Pickleball

- Provides tournament-level bounce

- Resistant to cracks and peeling

- Suitable for multi-sport conversion

- Long lifespan with minimal maintenance

- Available in multiple color combinations

Because pickleball involves quick lateral movement, slip resistance and shock absorption are critical — both provided effectively by acrylic flooring systems.

Transform Your Sports Facility Today!

Contact us for high-quality synthetic sports flooring material and elevate your space!

Maintenance Tips for Long-Lasting Pickleball Courts

- Regular cleaning with water and soft broom

- Avoid harsh chemicals

- Inspect cracks annually

- Reapply color coating after 5–7 years if required

- Ensure proper drainage to avoid water accumulation

Proper maintenance increases court lifespan significantly.

Final Thoughts

Successful pickleball court construction requires careful planning, accurate pickleball dimensions, high-quality pickleball court flooring material, and a professional pickleball builder. Choosing the right surface system ensures player safety, consistent performance, and long-term cost efficiency.

With the growing popularity of pickleball in India, investing in a professionally built court offers both recreational and commercial opportunities.

Frequently Asked Questions (FAQs)

The standard court size is 20 feet wide and 44 feet long, with a 7-foot non-volley zone on each side of the net.

Synthetic acrylic flooring is considered the best option due to durability, weather resistance, and consistent ball bounce.

Typically 3–5 weeks depending on site conditions and weather.

Yes, with proper resurfacing and marking adjustments.

Costs range from ₹6 lakh to ₹12 lakh depending on material quality and additional features.