When planning an outdoor sports court base in India—whether for tennis, basketball, volleyball, pickleball, or multi-sport arenas the most important decision is choosing the right sport court base type. Two options dominate today: concrete and bitumen base for the sports court. While concrete is traditionally used, modern high-performance outdoor courts prefer a bitumen base for sports court construction because of its flexibility, drainage performance, lower cracking, and excellent compatibility with synthetic acrylic flooring on bitumen.

Top Flooring is one of India’s most trusted names when it comes to synthetic acrylic sports flooring. With 14 years of experience, we cover over 800 thousand square feet of built-up area and 2000+ completed projects in India. Top Flooring delivers premium surfaces that are long-lasting and durable, featuring 9 standard court colours and color customization options. This expert guide explains what a bitumen base is, how it is built, how it compares to concrete, and why it is considered one of the most cost-effective sport court construction options in India.

What Is a Bitumen Base?

A bitumen base is formed by compacting layers of aggregates, sand, mineral filler, and hot bitumen binder to create a strong, flexible, and long-lasting foundation for outdoor sports courts. It acts as a durable blacktop layer designed to support acrylic coatings, offering the stability and smoothness required for professional sports performance. In simple terms a bitumen base is a flexible, weather-resistant bitumen foundation engineered to deliver consistent playability and reduced surface cracks under acrylic sports flooring.

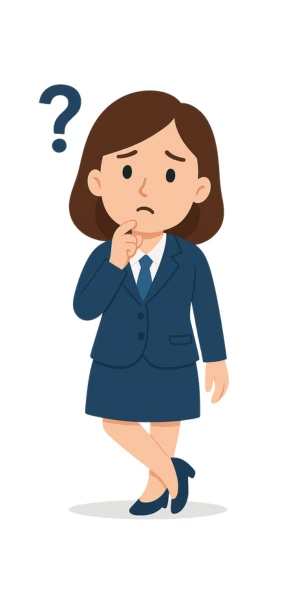

Unlike road bitumen, a sports court bitumen base requires:

Smoother finish

Sports courts require a finer, more polished bitumen finish to ensure the acrylic layers adhere evenly and the final surface feels uniform underfoot. This smoothness eliminates bumps or surface irregularities that can affect ball speed, bounce, and player safety.

Finer aggregates

Finer aggregates are used so the surface stays compact, tightly bound, and free from loose stones that could damage acrylic coatings or disrupt play. This results in a cleaner, denser surface specifically suitable for tennis, basketball, pickleball, and other precision-based sports.

Tighter tolerances

Sports courts demand precise leveling and thickness control, allowing the bitumen layer to remain perfectly even across the entire playing area. This accuracy ensures consistent performance, preventing dead spots, dips, or uneven bounce.

Precise slope (1%)

A strict 1% slope is required to drain rainwater quickly without affecting gameplay or causing waterlogging during monsoon conditions. This engineered slope helps maintain the lifespan of acrylic layers and prevents standing water from damaging the surface.

Better compaction

High-density compaction ensures the bitumen base remains stable, crack-resistant, and capable of withstanding continuous player movement. Proper compaction strengthens the surface and prevents future depressions, waviness, or structural failure.

This ensures the surface is ready for synthetic acrylic flooring on bitumen, which requires superior uniformity for ball bounce and performance.

Where Is Bitumen Base Used in Sports Court Construction?

Tennis Courts

Bitumen base is ideal for outdoor tennis courts because it offers a smooth, uniform, and flexible surface that supports consistent ball bounce. Its lower cracking rate makes it more durable under India’s heat and monsoon cycles.

Basketball Courts

Outdoor basketball courts often use bitumen because its flexibility absorbs surface stress, reducing cracks and undulations. The smooth bitumen finish also supports better traction and long-term performance.

Volleyball Courts

Volleyball courts in schools, societies, and clubs prefer bitumen base due to its excellent drainage and weather resistance. It ensures a safer, non-slip foundation for acrylic coatings in outdoor settings.

Pickleball Courts

Pickleball courts use a bitumen base for its stability and controlled surface movement, which maintains accurate ball bounce. It also performs better against rainwater and temperature fluctuations than concrete.

Outdoor Badminton Courts

Outdoor badminton court installations rely on bitumen base because it minimizes cracking and ensures an even surface for gameplay. Its compatibility with acrylic layers makes it suitable for all-weather use.

Multi-Purpose Sports Courts in Schools & Societies

Multi-sport areas favor bitumen due to its versatility and ability to support many games on one court. It is cost-effective and easy to maintain, making it ideal for high-traffic public and institutional spaces.

Public Parks

Public recreational courts in parks commonly use bitumen because it is durable, low-maintenance, and withstands heavy footfall. It provides a stable, long-lasting foundation for community sports activities.

Institutional Playgrounds

Schools, colleges, and universities choose bitumen bases for their playground courts as they offer long lifespan, easy rehabilitation, and better outdoor performance. They also reduce long-term repair and maintenance costs of sports courts.

Sports Court Construction Base Types in India

The two main sports court bases are:

1. Bitumen Base

A bitumen base is a flexible, smooth, and weather-responsive foundation widely used for outdoor acrylic sports courts. It adapts well to Indian heat and monsoon cycles, resulting in fewer cracks and better long-term performance.

2. Concrete Base

Concrete base is a rigid and high-strength foundation often used for indoor or heavy-load sports structures. However, due to its low flexibility and higher tendency to crack outdoors, it is less suitable for India’s varying temperatures and rainfall.

Why Bitumen Is Preferred for Outdoor Courts in India

Bitumen offers superior climate adaptability, faster installation, improved drainage, and greater compatibility with acrylic sports flooring systems. This makes it the preferred outdoor sports court base in India compared to concrete.

Bitumen Base vs Concrete Court Base

| Factor | Bitumen Base | Concrete Base |

| Flexibility & Cracking | High flexibility allows smooth expansion and contraction, resulting in significantly fewer cracks over time. | Rigid structure cannot absorb movement, leading to frequent cracks that impact playability and surface quality. |

| Drainage Performance | Excellent drainage when built with a 1% slope, allowing fast rainwater runoff during Indian monsoon conditions. | Prone to water stagnation as minor unevenness can trap water, increasing maintenance and harming acrylic coatings. |

| Durability | More durable outdoors due to heat adaptability and resistance to thermal expansion, ideal for Indian climate. | Becomes brittle under extreme heat or temperature changes, causing cracks and long-term structural failures. |

| Compatibility With Acrylic Flooring | Ensures strong bonding with acrylic resurfacers and cushion layers, maintaining long-term adhesion. | Often needs additional primers or correction layers to achieve similar adhesion, raising cost and installation time. |

| Construction Speed & Cost | Faster construction with no long curing period; bitumen courts can receive acrylic within 24–48 hours. Cost-effective across India. | Slower construction due to long curing time; higher material and labor costs make it less economical. |

| Overall Performance (India) | Superior foundation for outdoor sports courts due to flexibility, drainage, durability, speed, and acrylic compatibility. | Less suitable for outdoor courts; increased cracking and drainage issues reduce long-term reliability. |

Step-by-Step Process: How a Bitumen Base Is Constructed

1. Earthwork & Marking

The site is cleared of vegetation, debris, loose soil, and obstacles to create a clean working surface. Accurate boundary marking ensures the court dimensions and layout are aligned with the final sports flooring plan.

2. Sub-Grade Preparation

The natural ground is compacted to 95% Proctor density to provide a stable base that prevents future settlement or unevenness. Proper grading ensures the ground is level and ready to support the upper structural layers.

3. Sub-Base Construction

A GSB/WMM layer is laid to provide load-bearing capacity and distribute weight evenly across the court foundation. This layer also helps in achieving uniform compaction and long-term structural strength for the sports court base.

4. Base Course Application

A 40–50mm bitumen base course is applied using a hot mix to form the first strong structural layer of the bitumen court base. This layer is compressed while hot using an 8–10 ton roller to reach maximum compaction and density.

5. Wearing Course Application

A fine bitumen wearing course (25–30mm) is applied to create a smooth, uniform, and crack-resistant surface layer. This layer must be perfectly leveled and seamless, as it directly impacts the performance of the acrylic sports flooring system.

6. Slope Correction

A precise 1% drainage slope is maintained across the surface to ensure efficient water runoff during rain. This prevents waterlogging, puddles, and long-term damage to acrylic coatings.

7. Cooling Time

The newly laid bitumen must cool and cure for 24–48 hours to stabilize before applying acrylic coatings. This ensures proper bonding of resurfacer, cushion layers, and color coats and prevents trapping of heat or moisture.

8. Acrylic Sports Flooring System

The system begins with primer and acrylic resurfacer to fill pores and create bonding with the bitumen surface. Cushion layers, color coats, and precise line marking are then applied to deliver a professional, durable, and high-performance sports court.

Pros & Cons of Bitumen Base for Sports Courts

Pros

Flexible & Low Cracking

A bitumen base naturally expands and contracts with temperature changes, reducing the chances of surface cracks. This flexibility ensures long-lasting stability for high-performance outdoor courts.

Ideal for Synthetic Acrylic Flooring

Acrylic resurfacer bonds exceptionally well to bitumen, creating a seamless and durable sports surface. This compatibility enhances bounce quality, grip, and overall playing experience.

Faster Construction

Bitumen courts require no long curing time, allowing installation to be completed much quicker than concrete. This makes it ideal for projects with tight timelines or fast delivery requirements.

Better Drainage

With a properly built 1% slope, bitumen sheds rainwater faster and minimizes surface water accumulation. This significantly reduces surface damage and ensures more playable days during monsoon.

More Cost-Effective

Bitumen base construction uses locally available materials and less curing time, reducing overall project costs. It also lowers long-term repair and maintenance expenditure.

Smoother Playing Surface

A well-laid bitumen wearing course provides a uniform, even finish that enhances ball bounce and player comfort. This smoothness is essential for sports like tennis, basketball, and pickleball.

Suitable for Indian Climate

Bitumen performs well in India’s extreme heat and heavy monsoon cycles due to its flexible and water-resistant nature. It withstands temperature variations better than rigid concrete bases.

Cons

Requires Skilled Bitumen Team

Proper bitumen mixing, levelling, and rolling demand experienced technicians and the right equipment. Without skilled workmanship, surface quality and longevity can be compromised.

Poor Compaction Leads to Depressions

If the base course is not compacted uniformly, the court can develop potholes or low spots over time. These depressions affect drainage and create uneven playing conditions.

Heat-Sensitive

Using an improper bitumen grade may cause the surface to soften or deform in high temperatures. Ensuring the correct bitumen mix is essential for long-lasting outdoor sports courts.

Cleaning and Maintenance

Bitumen courts require periodic cleaning, crack filling, and resurfacing every few years. Neglecting maintenance can reduce lifespan and affect surface performance.

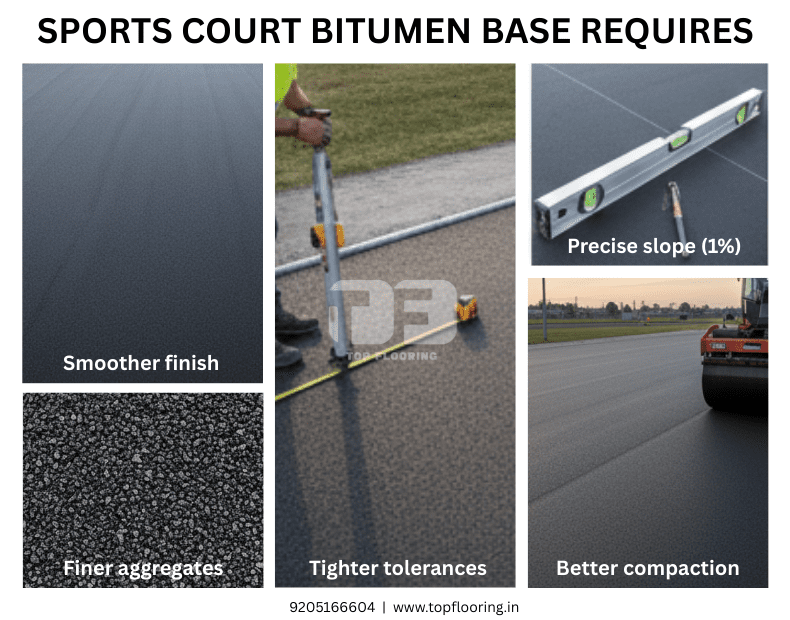

Maintenance of Bitumen Courts

- Annual cleaning: Regular sweeping and washing help prevent dust, algae, and debris buildup that can affect traction and player safety. Keeping the surface clean also protects the acrylic layers from premature wear.

- Quick water removal: Standing water must be cleared immediately to prevent moisture penetration, surface softening, and acrylic coat damage. Faster drainage and water removal extend the lifespan of the bitumen base.

- Crack filling: Any minor cracks should be repaired as soon as they appear to prevent expansion caused by heat, moisture, and movement. Timely crack filling maintains surface uniformity and prevents costly structural repairs.

- Acrylic resurfacing every 4–6 years: A fresh layer of acrylic resurfacer restores grip, color, and bounce consistency while sealing the underlying bitumen. This periodic resurfacing significantly increases the lifespan and performance quality of the sports court.

The Lifespan of a Bitumen Court

A properly constructed bitumen sports court lasts 5–7 years without major repairs. This durability comes from its flexible structure, which handles India’s temperature changes and reduces cracking compared to rigid concrete bases. With periodic resurfacing, a bitumen court can easily last over 8 years. Regular acrylic recoating restores surface smoothness, strengthens the top layer, and prevents long-term deterioration, significantly extending the court’s service life. This makes bitumen one of the most durable options for outdoor Indian sports courts. Its long lifespan, low maintenance needs, and strong compatibility with acrylic systems make it the preferred choice for long-term, cost-effective sports infrastructure.

Cost of Bitumen Court Construction in India

The cost of constructing a bitumen sports court base in India depends on multiple factors such as site location, soil condition, availability of machinery, and the current market rate of aggregates and bitumen. Prices also fluctuate based on transportation distance and the thickness of the sub-base, base course, and wearing course required for the project.

A standard bitumen base for sports courts typically ranges between ₹80–₹180 per sq ft, covering only the bitumen layers and structural preparation. The acrylic surface system—primer, resurfacer, cushion layers, and color coats—is charged separately, as its cost varies according to the chosen sport and performance level. Overall, bitumen construction remains one of the most cost-effective court construction methods in India, offering an excellent balance between durability, performance, and long-term value for outdoor multi-sport facilities.

Conclusion

A bitumen base is one of the most reliable and cost-effective foundations for outdoor sports courts in India. Its flexibility, excellent drainage, faster construction time, and compatibility with acrylic surfaces make it ideal for tennis courts, basketball courts, volleyball courts, pickleball courts, and multi-sport arenas. When constructed with proper sub-base, base course and wearing course, and correct slope, bitumen courts offer long lifespans, reduced maintenance, and consistently high performance. For developers, schools, housing societies, and sports contractors seeking a durable outdoor sports court base in India, bitumen/asphalt base remains the most practical and performance-driven choice. Choose Top Flooring for premium synthetic acrylic sports court flooring.

Frequently Asked Questions

A compacted bitumen foundation used to support acrylic sports flooring.

Yes, bitumen vs concrete tennis court comparison favors bitumen due to flexibility and reduced cracking.

Tennis, basketball, volleyball, badminton, pickleball, and multi-sport courts.

The ideal bitumen base thickness is 60–80mm across base course and wearing course.

12–18 years, extendable to 20+ years with resurfacing.

Yes, bitumen is the best base for acrylic sports flooring.

1% slope for ideal drainage.