Basketball is not just a sport today it has become a lifestyle and a symbol of fitness, teamwork and community. Across India the demand for basketball court flooring and professional basketball court construction is growing rapidly. Schools are building courts to promote sports culture, housing societies are adding them as modern amenities, and academies are investing in them for professional training. Even homeowners are looking for basketball court home installation as a value addition to their property.

When searching for the right partner most people start with queries like “basketball court makers near me.” But finding a trusted company is not just about convenience, it’s about quality. The choice of basketball court material, the expertise of the basketball court builders and the clarity in basketball court installation cost can make or break your investment.

This blog will cover everything you need to know: the types of basketball court flooring, the step by step outdoor basketball court installation process, the actual outdoor basketball court construction cost in India and tips on selecting the best basketball court manufacturers who can deliver both performance and durability. Whether you’re a school, a sports academy, a housing society or an individual looking for cheap outdoor basketball court flooring without compromising on quality this guide will help you make the right decision.

What Makes a Good Basketball Court Maker?

When you search for basketball court makers near me, you’ll find many names but not all deliver the same. A good basketball court manufacturer or builder should have these qualities:

- Use certified materials – High quality basketball court material, especially acrylic systems, are tested for bounce, grip and UV resistance. So the players get consistent performance and flooring remains vibrant and safe under Indian weather. Courts made with uncertified or low grade materials fade, crack or become slippery soon.

- Multiple flooring options – A professional maker offers solutions beyond one surface type. From indoor wooden courts for stadiums to outdoor acrylic courts for schools and societies and even multipurpose flooring for clubs, variety shows their technical expertise.

- Offer end to end service – Good basketball court construction companies handle everything from site preparation and base work to outdoor basketball court installation and final line markings. They also provide long term support through maintenance and resurfacing so the court remains functional and attractive for years.

- Transparent pricing – Honest builders explain the basketball court installation cost in detail – base, flooring system, coatings and add-ons like fencing or lighting. So there are no hidden charges and clients can compare with other vendors.

- Durable Court – Outdoor courts are exposed to rain, dust and heat. The right outdoor basketball flooring material, especially acrylic with UV resistant coatings gives long lasting performance.

What are the Types of Basketball Court Flooring?

1. Acrylic Basketball Flooring

Acrylic is the most popular choice for outdoor basketball courts in India as it performs well in sun, rain and dust. It has good grip, consistent ball bounce and reduces the chances of slipping. This system requires minimal maintenance as compared to wooden or modular surfaces making it ideal for schools, clubs and societies.

2. Concrete Base with Coatings

Many schools and housing societies prefer concrete basketball courts as they are cost effective and easy to install. When coated with acrylic and colored, the court becomes safer, more attractive and suitable for casual to intermediate play. Though it may not have the comfort of cushioned acrylic systems, it is a budget friendly option for community spaces.

3. Wooden Indoor Courts

Wooden basketball courts are the traditional standard for professional and international indoor arenas. They provide superior ball response, comfort and aesthetic court. Which makes them ideal for high level competition. But not recommended for outdoor use in India as it is prone to moisture, weather changes and long term maintenance challenges.

4. Modular PP Tiles

Modular polypropylene (PP) tiles are interlocking surfaces that can be installed and removed quickly making them a flexible option for temporary or multi purpose spaces. They are durable, customizable and available in different colors. But expand in heat and do not have the same stability or bounce quality as acrylic for outdoor use.

Comparison of Basketball Court Flooring Types

| Flooring Type | Best For | Advantages | Limitations | Cost Level | Indoor/Outdoor Use |

| Acrylic Flooring | Schools, societies, clubs, academies | Strong grip, consistent bounce, UV & weather resistance, low maintenance | Needs proper base preparation for durability | Medium | Best for Outdoor |

| Concrete + Coatings | Housing societies, budget projects | Affordable, durable base, improved safety & looks with acrylic coating | Less cushioning, can crack if base is not well-prepared | Low | Outdoor |

| Wooden Flooring | Indoor stadiums, professional games | Excellent ball response, aesthetics, professional standard | Expensive, not suitable outdoors, high maintenance | High | Indoor only |

| Modular PP Tiles | Temporary or multi-purpose setups | Easy installation, portable, customizable, replaceable tiles | Expands in heat, less stable than acrylic, costly for large areas | Medium–High | Indoor & Outdoor |

Basketball Court Construction Process

Building a basketball court is more than just painting a surface. It requires planning, precision and the right materials. Professional basketball court construction companies follow a step by step process to ensure the court is safe, durable and meets standards.

1. Site Preparation

The first step is site preparation. This includes clearing the land, levelling the surface and ensuring proper drainage so water doesn’t collect on the court. Good site preparation is the foundation of a strong and long lasting basketball court.

2. Base Work

Once the land is ready, a solid base is constructed usually with concrete or asphalt. The base must be stable, smooth and strong enough to handle heavy play. A bad base can cause cracks, uneven bounce and long term maintenance issues.

3. Layering System

The flooring system is applied in multiple layers to ensure durability and performance. It starts with a primer for adhesion, then a resurfacer to smoothen the base. Cushion coats can be added for comfort. Then color coats for aesthetics and finally line markings to define the court.

4. Final Testing

Before handing over the court the basketball court builders do final quality checks. They test the bounce of the ball, surface grip and overall safety of the court. This ensures the flooring meets performance standards for casual players and professional athletes.

In short this process ensures every court built is durable, safe and suitable for long term use—whether in schools, housing societies, clubs or private homes.

Outdoor Basketball Court Flooring in India

Indian summers, monsoons and dust make outdoor courts a challenge to maintain. That’s why acrylic outdoor basketball flooring has become the go to choice for long lasting performance.

- Weather resistance: Acrylic flooring is designed to withstand extreme heat and heavy rainfall, perfect for Indian weather. Unlike low grade coatings that peel off, a proper acrylic system stays strong and maintains grip even after years of outdoor exposure.

- UV protection: Strong sun exposure makes cheap paints fade quickly, but acrylic systems have UV resistant pigments. This ensures the court looks professional and vibrant for many years even under direct sun.

- Anti-slip texture: Outdoor basketball courts are exposed to dust and occasional moisture. The textured surface of acrylic flooring provides excellent traction, reduces the risk of slips and ensures safe play in all conditions.

- Budget friendly options: Not every project requires a premium system. Acrylic flooring is available in standard systems and cheap outdoor basketball court flooring solutions, perfect for housing societies, schools and community playgrounds.

Basketball Court Installation Cost

Basketball court installation cost in India depends on many factors. Knowing these helps in planning a budget friendly basketball court that suits you.

- Court size – A full basketball court costs more than a half-court. Because of the larger playing area, it requires more materials and labor. Half-basketball courts in housing societies or villas are budget-friendly options while still offering great play value.

- Indoor vs outdoor – Indoor wooden courts are premium installations used in professional stadiums and require controlled environment, hence more expensive. Outdoor basketball court flooring with acrylic material is more affordable, low maintenance and suitable for Indian weather.

- Number of layers – Cushion coats add extra comfort and reduce impact on players’ knees and ankles. But each additional layer increases the basketball court installation cost. Schools and academies prefer cushioned systems for player safety.

- Add-ons – The final cost also depends on what you add to the court like fencing for safety, high-mast LED lighting for evening play and logos or custom color designs for branding. These add-ons enhance the experience but increase the budget.

- Location – Transporting basketball court material and arranging skilled labor in remote or far-off locations can increase costs. Projects in metro cities have easier access to material, reducing logistics cost.

Approximate Outdoor Basketball Court Construction Cost

- Half-court (housing societies or villas): Smaller in size, these are budget-friendly installations that save on material and space. They are ideal for community recreation or personal use at home.

- Full-court (academies, schools, clubs): Though costlier due to size and add-ons, full-court installations provide a complete professional experience. They offer long-lasting value, especially for training and competitive play.

How to Choose the Best Basketball Court Makers in India?

When investing in basketball court construction, the maker you choose is as important as the material used. The right basketball court makers will give you a court that is durable, safe and cost effective. Here are the top factors to consider:

1. Experience and Track Record

Look for basketball court builders who have experience in schools, housing societies, academies and clubs. A maker who has done multiple projects can handle site challenges better and give you long lasting results.

2. Quality of Basketball Court Material

The flooring system decides how your court will perform. Certified basketball court material, especially acrylic flooring will give you good bounce, grip and resistance to Indian weather.

3. Transparency in Basketball Court Installation Cost

Reliable basketball court construction companies will give you a clear cost breakdown – base preparation, flooring layers, line marking, equipment, fencing and lighting. Transparent pricing will avoid hidden costs.

4. Outdoor vs Indoor Expertise

Not all makers are experts in both. Ensure they have solutions for outdoor basketball court construction with UV resistant acrylic flooring and indoor options like wooden flooring for professional stadiums.

5. Maintenance and Resurfacing Support

Courts need maintenance to be safe and look good. The best basketball court manufacturers will also provide resurfacing services, crack repairs and repainting. So that your investment lasts for years.

Why Top Flooring is a Reputed Basketball Court Manufacturer?

Top Flooring stands out among top basketball court contractors in India because:

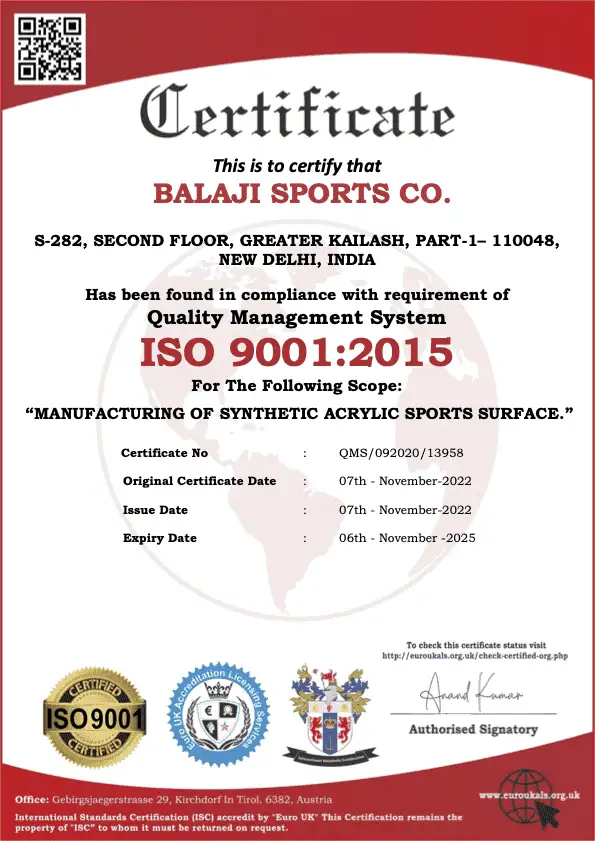

- Top Flooring builds every court with ITF-approved, ISO-certified acrylic systems. These are durable, UV resistant and offer consistent performing systems that are suitable for Indian climate and heavy play.

- Whether it’s a half court for a villa, a multipurpose court for housing societies or a professional grade surface for academies. Top Flooring customizes its basketball court construction solutions to fit every budget, space and player requirements.

- Clients get a clear and detailed basketball court cost breakdown which includes base preparation, flooring layers, line marking, equipment and add-ons. This eliminates hidden costs and builds trust with customers across India.

- With a wide dealer presence across major cities and towns. Top Flooring ensures faster installation, easy access to materials and quick response for repairs or resurfacing. This local support adds long term value to every project.

- From outdoor acrylic courts in housing complexes to premium courts in schools. Top Flooring has completed numerous projects across India. This experience helps deliver quality results in any environment.

Conclusion:

The best basketball court makers are those who understand the science behind outdoor basketball surfaces. And use certified basketball court material with transparent pricing for the entire project from base preparation to final line marking. After sales support is equally important. Resurfacing, repainting and minor repairs are essential to keep your court in top condition. A good basketball court manufacturer will ensure your investment gives you value for years to come.

At Top Flooring, we specialise in providing durable, ITF and ISO certified outdoor basketball court flooring systems for Indian conditions. From societies and schools to academies and private properties, our basketball courts are safe, stylish and strong.

If you are planning a new court or thinking of basketball court home installation, get in touch today for a free consultation. Let’s build a court that looks great and lasts because the right basketball court construction is the base of every great game.

Frequently Asked Questions

Acrylic is the best outdoor basketball court material due to its UV resistance, grip and all weather durability.

Yes, home basketball court installation is possible with half court or full court depending on space and budget.

Basketball court construction in India takes 3-6 weeks depending on site preparation, flooring layers and weather.

Acrylic basketball courts are better as they provide grip, bounce and low maintenance compared to basic concrete courts.

Yes, outdoor basketball courts need resurfacing every 4-5 years to maintain bounce, safety and color.