Behind every great serve and forehand it’s the tennis court flooring that makes all the difference. The bounce, grip, speed and safety of every shot depends on how scientifically the court is designed and built. In India, tennis is growing as a sport of recreation and competition. Schools, academies, clubs and residential projects are now investing in professional grade synthetic tennis court flooring instead of temporary painted surfaces. But building a tennis court is more than just a flat surface. But it requires planning, right materials and professional execution.

This guide by Top Flooring is India’s trusted name in synthetic acrylic tennis court construction covers every stage of the process: from planning and base preparation to surface selection, costs and long term maintenance.

Understanding the Basics: What Makes a Good Tennis Court?

A well built tennis court is not just about the color or looks. It’s a combination of precise measurements, proper slope, durable base and high performance surface layers. Each of these factors determines how the ball behaves, how comfortable the players feel and how long the court lasts.

Standard Tennis Court Dimensions

Every professional tennis court is built according to the International Tennis Federation (ITF) standards to ensure uniform play conditions worldwide. These dimensions are essential for fair competition, consistent ball response and player safety.

- Length: 78 feet (23.77 meters)

- Width: 36 feet (10.97 meters) for doubles / 27 feet (8.23 meters) for singles

- Total Playing Area: 2,808 sq. ft. (260.9 m²)

- Recommended Total Area (including run-off and safety zones): 120 ft x 60 ft (7,200 sq. ft.)

The extra space around the court is not optional. But it is necessary for player movement, safety and match visibility. It prevents collisions with boundaries and allows players to chase wide shots without injury risk. For institutional or tournament level setups, this outer safety zone is mandatory.

Indoor vs Outdoor Tennis Courts

While the layout remains the same, indoor and outdoor tennis courts differ in material selection and maintenance requirements.

Outdoor Tennis Courts:

Outdoor tennis courts are exposed to sunlight, rain, humidity and dust 24/7 and need highly durable systems. These courts require UV-resistant acrylic coatings, 1:100 drainage slopes and non-slip surface textures to withstand weather conditions and maintain playability throughout the year.

Indoor Tennis Courts:

Indoor courts being shielded from harsh weather can use smoother, less textured coatings and often have cushioned layers for extra comfort and shock absorption. They have a quieter bounce and are ideal for academies, sports complexes and all-weather facilities.

Regardless of where it is built, a professional tennis court must have uniform ball bounce, controlled surface friction and consistent pace rating with the characteristics of ITF classified flooring. These factors ensure fairness and player confidence in every match whether it’s played under open sky or a covered dome.

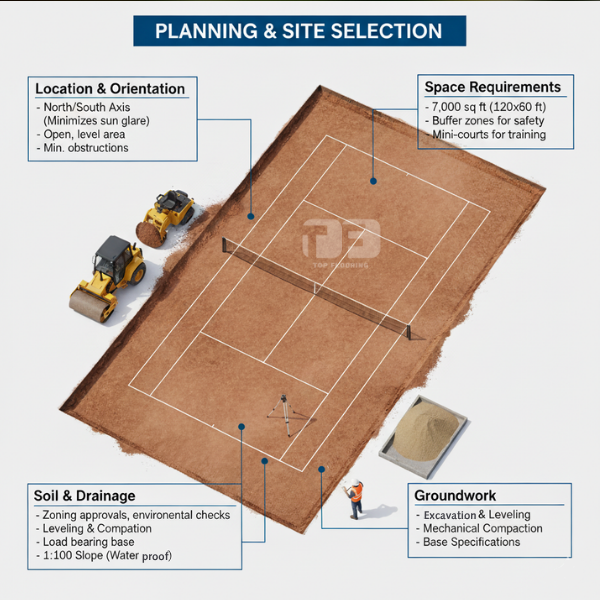

Planning and Site Selection

Before a single layer of coating is applied, a tennis court construction project is all about the foundation. Not just the physical base, but the location, orientation and groundwork preparation. A well chosen site minimizes future maintenance issues, player comfort and ensures your court performs all year round.

1. Location and Orientation

First you need to find an open, level area with natural drainage and minimal obstruction from trees or surrounding structures. Avoid sites with too much shade as falling leaves and moisture retention can damage the surface over time. The orientation of the court is also important. Professional builders always recommend a north–south axis. So players aren’t blinded by the rising or setting sun during matches. This orientation gives balanced lighting and visibility for both ends of the court throughout the day — a standard followed in ITF compliant facilities.

2. Space Requirements

A full size ITF standard tennis court requires approximately 7,200 square feet (120 ft x 60 ft) including buffer zones for safe player movement. This extended area allows players to move freely beyond the baseline and sidelines without the risk of injury or collision. For space-constrained projects such as residential clubs or multi-sport complexes, compact or mini tennis courts can be designed using the same synthetic acrylic flooring system. But with correct play proportions. These scaled down versions are ideal for training, youth programs or recreational use where full tennis court dimensions are not required.

3. Soil and Drainage Conditions

The life and performance of a court is heavily dependent on what’s beneath it. Before any tennis court construction begins the site’s soil composition, moisture retention and load bearing capacity should be professionally tested. Poorly compacted or clay heavy soil can lead to uneven settlement, surface cracks or water retention. All of which affect bounce uniformity and safety. The ground needs to be compacted to achieve stability and a uniform grade.

For effective water management, courts are built with a 1:100 (1 cm per meter) slope. This is almost invisible to the eye but ensures efficient rainwater runoff, no puddles and no algae growth. Proper drainage planning not only preserves the playing surface but also extends the life of the entire court structure.

4. Local Permissions and Groundwork

For public, institutional or government funded tennis court projects you will need to obtain construction permissions and compliance clearances. These may include zoning approvals, environmental checks and civil work safety regulations. Once permissions are in place groundwork begins with excavation, leveling and mechanical compaction of the sub-grade. The site is shaped according to design plans, slope gradient and base specifications (asphalt or concrete). This stage sets the foundation for every layer that follows from the primer to the topcoat. So that your tennis court will perform for years to come.

Tennis Court Base Construction

Every high-performance tennis court starts with one critical component and that is the base. This foundation determines how the surface plays, drains and lasts over time. A well-engineered base means proper bounce, long-term stability and low maintenance. While a poorly constructed one can lead to cracks, bubbles and uneven play within months. At Top Flooring, every project begins from the ground up, following engineering grade standards that match ITF guidelines for tennis court base construction.

1. Sub-Base Preparation

The sub-base is the foundation of everything that follows. Construction begins with site excavation, removing loose soil and organic matter to create a clean, compactable layer. Next, the area is backfilled with well-graded stone dust or granular material, compacted mechanically in layers to achieve uniform density. This compacted foundation prevents future settlement and maintains level across the entire court surface. Proper soil stabilization and compaction is crucial, especially in areas with high moisture content. Inadequate compaction can cause the court to shift resulting in cracks, poor drainage or inconsistent bounce.

2. Base Options

a) Asphalt Base:

Asphalt tennis court base is the most preferred foundation worldwide from club courts to major tournaments. Asphalt is a flexible yet stable platform that absorbs minor ground movements without cracking.

- Suitable for both outdoor and indoor courts.

- Provides smooth, seamless surfaces with excellent bonding to acrylic coatings.

- Allows for minor ground adjustments, suitable for variable soil conditions.

- Quick installation and easy repair makes it cost effective and reliable.

When done correctly, an asphalt base can last 20-25 years, requiring only surface resurfacing every few seasons.

b) Concrete Base:

A concrete base provides a rigid and highly durable foundation, best suited for permanent or high-traffic facilities like academies, schools and sports complexes.

- Offers excellent structural stability and minimal deformation.

- Requires expansion and contraction joints to manage temperature induced movement.

- Must be cured for at least 28 days before any acrylic coating is applied.

- Delivers faster ball pace and lower maintenance in the long run.

Concrete bases are popular in India because of their availability, cost effectiveness and resilience against heavy rainfall and soil shifts. When installed correctly and sealed, they are compatible with acrylic tennis court systems.

3. Slope

An invisible but critical component of every professional tennis court is the slope. The surface must be flat to the eye but engineered to drain water. A 1:100 (1 cm per meter) uniform slope ensures rainwater drains off the court without puddles. The slope should run laterally or diagonally depending on site drainage design, always towards drain lines or catch pits. Proper drainage prevents surface blistering, algae growth and color fading — the top 3 reasons for premature resurfacing.

4. Curing and Inspection

After the base is installed, it needs to go through a curing and inspection process before coating.

- Curing Period: Concrete takes a minimum of 28 days to fully hydrate and stabilize. Hurrying this process can trap moisture and cause delamination when coatings are applied.

- Moisture Testing: Before the primer layer, the surface should be tested for residual moisture to ensure it’s dry.

- Surface Inspection: Technicians check for cracks, low spots or undulations using straightedges and laser levels. Minor defects are corrected using leveling compounds or patch mixes before moving on to the acrylic layers.

A properly constructed base is what gives a tennis court its strength and longevity. It ensures every subsequent layer resurfacer, cushion and color coat adheres perfectly and performs as designed.

At Top Flooring, our base construction process follows strict engineering parameters for slope, compaction and curing, so the surface remains stable, durable and tournament ready for years. Because when the base is right, every bounce, serve and rally feels just right.

Choosing the Right Tennis Court Surface Material

Choosing the right tennis court surface material is one of the most important decisions in the entire process. It affects not only game quality but also maintenance cost, climate performance and player safety. Different courts serve different needs. From hard acrylic surfaces to cushioned systems and clay or turf variations, each has its own strengths. Let’s look at the main types and which surface is best for India.

1. Acrylic Hard Courts: The Global Standard for Performance and Durability

Acrylic hard courts are the most widely used tennis surfaces globally — in international tournaments, academies and sports complexes. Built with multiple layers of acrylic resin and silica sand, they offer unmatched durability and a professional feel.

Key Benefits:

- Longevity: Lasts 8–10 years with minimal maintenance when properly maintained.

- Consistent Bounce: Provides uniform ball response across the entire surface, suits all playing styles.

- Medium Pace: Not too fast, not too slow but it’s perfect for both recreational and professional matches.

- Weather Resistance: Performs well in outdoor environments, resists UV damage, fading and cracking.

- Low Maintenance Cost: Just clean and recoat every few years.

This is the same surface system used at US Open and Australian Open, both have medium paced, ITF rated hard courts. Acrylic hard courts are perfect for academies, clubs and housing societies looking for a professional grade surface that offers year round playability, long life and low maintenance.

2. Synthetic Cushioned Courts: Comfort Meets Performance

For facilities where player comfort and joint safety is top priority, cushioned acrylic systems offer the perfect balance between performance and protection. These surfaces have multiple layers of elastomeric compounds beneath the color coats to absorb impact and reduce player fatigue.

Why Choose Cushioned Tennis Courts:

- Shock Absorption: Reduces stress on knees, ankles and hips during intense play.

- Long Play Time: Comfortable for long training sessions, ideal for academies and coaching centers.

- All Weather: Works in both indoor and outdoor setups.

- Custom Cushioning: Cushion thickness can be adjusted to change comfort and pace as per player requirements.

Cushioned courts are slightly more expensive than standard acrylic courts but gives player well being and performance longevity, making them the preferred choice for training academies, universities and sports schools.

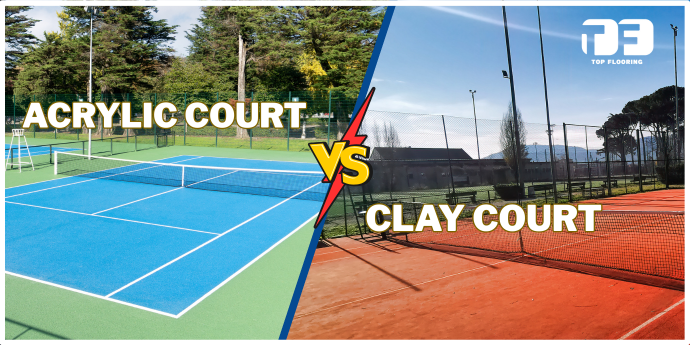

3. Clay or Turf Courts: Old School but High Maintenance

Clay courts and turf courts are traditional surfaces, common in European and South American tennis culture. While they offer different play experience, they are less suitable for Indian climate and maintenance.

Clay Courts:

- Slower ball pace with higher bounce, encourages longer rallies and tactical play.

- Needs constant rolling, watering and brushing to maintain surface uniformity.

- Maintenance is labor intensive and costly in hot or monsoon prone areas.

Turf Courts:

- Mimics natural grass surfaces and faster play.

- Needs regular trimming, infill adjustment and replacement after a few years.

- Surface wear and uneven traction under heavy use.

While both give different play experience, they are not practical for Indian weather, where humidity, dust and rain can damage natural or synthetic turf surfaces.

Why Acrylic is Best for India?

For Indian conditions, acrylic based tennis court flooring is the most reliable, economical and climate friendly option. It combines durability, performance and low maintenance. Which makes it the preferred surface for both private and institutional projects.

Advantages of Acrylic Tennis Court for Indian Climate:

- Handles Extreme Temperatures: Designed to resist thermal expansion under high heat and humidity.

- Quick Drying: Water drains and evaporates quickly, minimal downtime after rain.

- Slip Resistant: Special silica based texture prevents slipping even in monsoon humidity.

- UV and Fade Resistant: Keeps its colors intact under intense sunlight.

- Works with Multiple Bases: Works on both asphalt and concrete foundations.

- Easy to Resurface: Recoating every few years restores performance and looks with minimal effort.

For Indian weather and usage, ITF Category 3 acrylic systems give the perfect balance of comfort, speed and longevity. The same medium pace courts that professional players train on worldwide provide a consistent, safe and enjoyable playing experience for every match.

Tennis Court Layer Application Process (Step by Step)

Building a professional acrylic tennis court is a precise multi stage process of applying specialized coatings in a controlled sequence. Each layer plays a critical role in achieving the perfect balance of grip, bounce, durability and looks. When applied correctly these layers form a seamless, weather proof system that meets ITF performance standards and remains consistent for years.

Step 1: Primer

It all starts with the primer which is applied directly over the prepared concrete or asphalt base. This layer penetrates the surface and seals the microscopic pores so the structural base and synthetic system bond together. A good primer prevents peeling, moisture absorption and delamination which are common issues when surfaces are exposed to heat and humidity.

Step 2: Acrylic Resurfacer

Once the primer is dry the acrylic resurfacer layer is applied. This coating fills hairline cracks, evens out minor irregularities and provides a smooth surface for the next coatings. Made of acrylic latex and silica sand the resurfacer improves durability and uniformity. It helps the color coats adhere, strengthens the surface and keeps the pace of the court consistent across all play areas.

Step 3: Cushion Layers (Optional)

For cushioned tennis courts acrylic cushion layers are applied. These elastomeric coatings contain flexible compounds that absorb shock and reduce player fatigue. The number of cushion layers can vary depending on the desired feel of the court — more layers means a softer, slower surface for comfort and endurance training and fewer layers means a firmer, faster surface for competition play. This allows Top Flooring to customize each court to the specific requirements of academies, clubs or private installations.

Step 4: Color Coats

After the cushioning or resurfacer stage color coats are applied — usually in 2 or more layers. These coatings define the texture, pace and look of the court. The color system is made of UV stable, water based acrylic mixed with silica sand to control friction. The amount of sand determines the playing speed and the pigment the desired color. Common colors like royal blue, dark green and red are not only visually striking but also chosen for visibility and contrast against the tennis ball. Each coat must dry before the next is applied to ensure a uniform and durable finish.

Step 5: Line Marking

The final step is line marking where precision is key. Using abrasion resistant, non-glare white paint technicians mark the official ITF standard play lines with exact measurements. These markings are highly opaque to be visible under daylight and floodlights. Proper line application ensures the court meets competitive standards and looks professional.

Curing Time

Curing is critical to this process. Each layer takes 6 to 24 hours to dry depending on temperature and humidity. Ideal application conditions are between 10°C and 40°C with moderate humidity to prevent moisture from getting trapped in the coatings. Once all layers are dry the surface is inspected for evenness, adhesion and color consistency before it’s game ready.

A court constructed using this layered system delivers the perfect balance of speed, comfort, and resilience. At Top Flooring, every layer — from primer to topcoat — is formulated using advanced resins and UV-resistant compounds that can withstand India’s demanding climate. The result is a tennis court that not only looks vibrant but also provides reliable, tournament-grade performance season after season.

Cost of Building a Tennis Court

The tennis court construction cost varies based on location, materials, and design preferences.

1. Cost Breakdown (Approximate Range for India)

| Component | Details | Estimated Cost (₹) |

|---|---|---|

| Base Preparation | Concrete or asphalt base work | 8–9 lakh |

| Synthetic Acrylic Materials (5-Layer) | Standard cushioned system | 4–5 lakh |

| Synthetic Acrylic Materials (8-Layer) | Premium cushioned system | 6 lakh |

| Total Estimated Cost (5-Layer System) | Base + 5-layer acrylic flooring | 12–14 lakh |

| Total Estimated Cost (8-Layer System) | Base + 8-layer acrylic flooring | 14–15 lakh |

(Prices vary depending on court size, material brand, and site conditions.)

2. Cost Factors

- Type of surface (cushioned vs. non-cushioned)

- Choice of base (asphalt or RCC)

- Site accessibility and civil work costs

- Brand of coating material

- Additional features like fencing, drainage, or floodlights

3. Resurfacing and Maintenance Costs of Tennis Court

Every 5–7 years resurface to get grip and pace back. Tennis court resurfacing costs range from ₹3–5 lakh depending on system and wear.

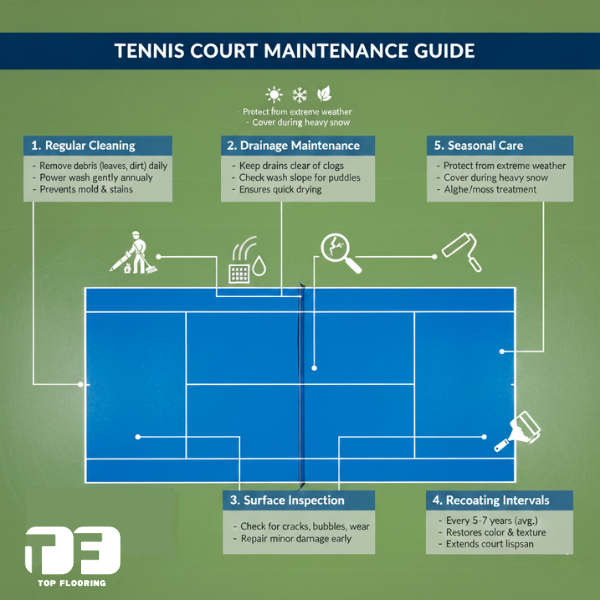

Maintenance and Longevity Tips

A well built tennis court is a long term investment and with proper care it can last more than a decade. A well built acrylic tennis court can last 10–15 years with minimal maintenance if cleaned regularly, inspected on time and resurfaced at the right intervals. Consistent maintenance not only enhances the playing experience but also avoids costly repairs in future.

1. Regular Cleaning

Regular cleaning is the simplest yet most important maintenance practice. Dust, leaves and debris can accumulate on the surface reducing traction and affecting the appearance of the court. Use soft bristled brooms, leaf blowers or water jets to clean the court without damaging the acrylic coating. Also avoid harsh cleaning chemicals — mild detergent and water is sufficient to remove stains or marks.

2. Drainage Maintenance

Proper drainage maintenance is crucial to extend the life of the court. All drain outlets and surface slopes should be free from obstructions like sand, leaves or algae buildup. Standing water can weaken the surface layers over time and lead to premature fading or blistering. A quick visual check after heavy rainfall ensures the water is draining properly and not pooling in any area.

3. Surface Inspection

Regular surface inspection is another key step. Every 6 to 12 months the court should be checked for small cracks, low spots or fading patches. Addressing these early prevents the need for complete resurfacing. Small imperfections can be repaired using compatible acrylic patching compounds to restore the court’s evenness and grip.

4. Recoating Intervals

Every few years it’s important to recoat the court with fresh color layers. Apply new ITF-rated acrylic coatings every five to six years to maintain consistent ball bounce, optimal friction and vibrant appearance. These coatings also add a protective layer that shields the court from UV exposure, heavy play and weather extremes.

5. Seasonal Care

Seasonal care helps in longevity. In coastal or humid areas, occasional cleaning with anti-algae or anti-fungal solutions helps in preventing mold and discoloration. During monsoon season, cover the surface when not in use to protect it from prolonged water exposure. Simple preventive steps like these and the court will be playable all year round.

By following these simple yet essential maintenance practices a Top Flooring tennis court will look new and perform like a professional surface long after installation. Designed for India’s climate, these courts are built to last, requiring only light periodic care to stay vibrant, reliable and tournament ready year after year.

Common Mistakes to Avoid During Tennis Court Construction

Even small mistakes in planning or execution can lead to big performance issues. Avoid these common mistakes in tennis court construction:

- Flat Surface: No slope, no drainage, puddles and algae formation.

- Untested Paints or Coatings: Local paints fade, crack or lose friction in a few months.

- Not Curing: Applying coatings before base curing leads to peeling or bubbling.

- Weak Base: Inadequate compaction or reinforcement leads to cracks.

- Wrong Layer Ratios: Unbalanced sand to resin ratio affects court pace and grip.

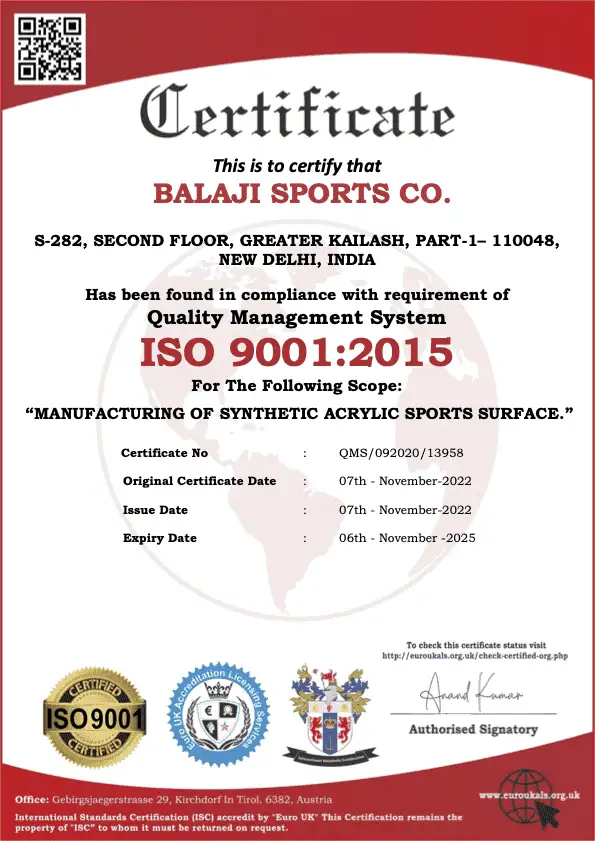

Working with experienced manufacturers like Top Flooring ensures every layer meets ITF performance benchmarks and installation best practices.

Why Choose Top Flooring for Tennis Court Construction

When it comes to tennis court builders in India, Top Flooring stands out for its engineering precision, ITF aligned products and nationwide expertise. Our acrylic tennis court systems are designed for India’s climate—UV resistant, fast drying and flexible under heat and humidity. Each material batch is tested for adhesion, elasticity and pace consistency to ensure world class performance. Top Flooring offers complete project management from base construction to final line marking. Our trained applicators follow ITF recommended layering techniques and curing cycles to deliver perfect results every time.

Whether it’s a school project, sports academy or private residence, we provide customized court designs as per space, budget and pace preference. Our surfaces meet ITF Category 3 (Medium Pace) standards—perfect for multi purpose, long term use. From consultation to execution, Top Flooring ensures your tennis court is built to last, play beautifully and meet global standards.

Conclusion

Building a tennis court is an art and science. It requires precision at every stage—design, base construction, coating and finishing. Cutting corners may save money temporarily but leads to uneven play, cracks and early resurfacing costs.

A properly built ITF standard acrylic tennis court offers consistent bounce, safe traction and professional grade playability for more than a decade. By choosing Top Flooring, you’re investing in expertise, certified materials and long term reliability. Our courts are designed for performance, tested for durability and built for Indian climate. When you build with Top Flooring, you’re not just building a court—you’re building a play, precision and performance legacy. Contact Top Flooring — India’s tennis court builders today.

Frequently Asked Questions

Asphalt with an acrylic coating is the cheapest tennis court surface, offering durability and good play quality at a low installation cost.

In India, building a standard acrylic tennis court typically costs between ₹15 lakh and ₹25 lakh, depending on the base, surface system, and location.

Yes. A well-built tennis court adds property value, supports fitness, and can generate income for clubs, academies, and housing projects.

Tennis can be affordable when played on low-maintenance synthetic or acrylic courts; costs mainly depend on surface type and facility upkeep.

Asphalt-based acrylic systems are the least expensive and most practical choice, combining low installation cost with long-term durability and easy maintenance.