Over the past few years, India has witnessed a complete shake-up in the sporting world. Cricket still holds the top spot, but basketball and pickleball are steadily growing in popularity. Schools, colleges, housing societies, and private clubs across the country are now investing in basketball court construction and pickleball court flooring in India. Pickleball, in particular, has surged because it’s so easy to learn you don’t need to be a professional athlete to play. The rules are simple, the courts are compact, and the game welcomes players of all ages. Beyond metro cities, even small towns and villages are embracing the sport, with communities actively looking for synthetic acrylic flooring that provides safe, long-lasting, and professional-grade courts for both recreational and competitive matches.

This surge in popularity is driving huge demand for top-notch courts, and traditional cement courts just don’t work under Indian weather conditions. They fail to provide a safe or satisfying playing surface. Synthetic acrylic sports flooring solves this problem with a consistent grip that lasts for years in both basketball and pickleball. With ITF and ISO-certified flooring now available in India, players and facilities no longer need to settle for poor-quality surfaces. This marks the start of a whole new era for sports in India, where basketball and pickleball thrive on proper professional acrylic courts.

What is Synthetic Acrylic Flooring?

Synthetic acrylic sports flooring is a no-fuss, seamless coating system that contractors apply directly over concrete or asphalt to create play areas that are both safe and durable. Manufacturers make it using water-based resins, colored coats, and silica sand keeping the process straightforward. This flooring gives players fantastic grip, consistent bounce, and long-lasting performance that keeps courts in top shape for years.

This particular type of acrylic flooring has become a winner in India, covering countless basketball court flooring, pickleball courts, and multi-sport surfaces. It stands up well to the elements, resisting UV rays, heavy downpours, and the daily wear and tear that outdoor floors face. You can also add extra cushioning to reduce impact and make play more comfortable for athletes.

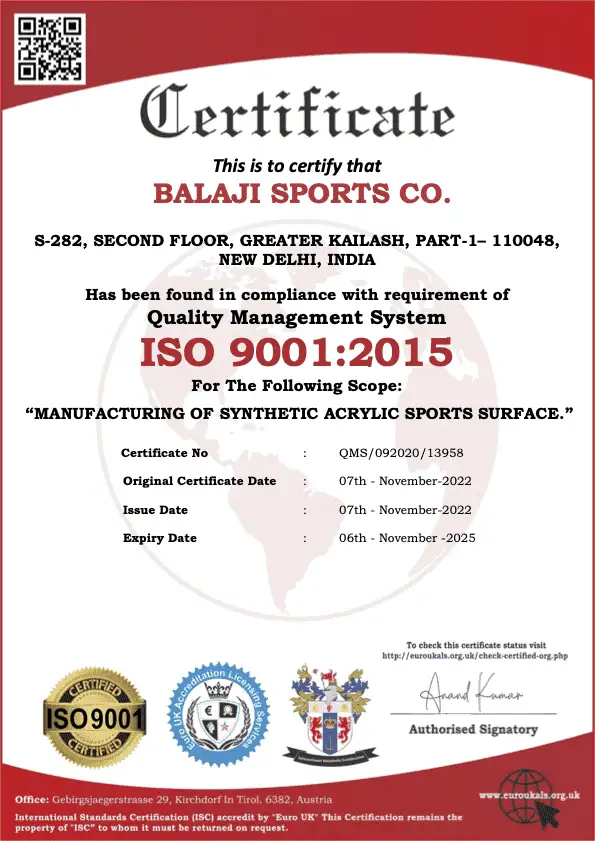

You can get pretty modern sports flooring in all sorts of colors these days, complete with clear line markings, it all comes in at a pretty affordable price. Plus, it’s got ISO certification, so you know you’re getting the same level of performance as you would with any of the big global flooring systems just suited to the Indian conditions.

Why Synthetic Acrylic Flooring is the Best?

When it comes to building basketball and pickleball courts in India, synthetic acrylic sports flooring is the way to go. It’s durable, safe and cost effective for schools, clubs, housing societies and academies.

- All Weather Performance: Acrylic flooring withstands Indian heat, rain and UV without fading or cracking.

- Consistent Play Quality: Provides steady bounce and grip for both basketball and pickleball.

- Player Comfort: Cushion systems in acrylic sports flooring reduces impact on joints so you can play longer and safer.

- Low Maintenance: Easy to clean, recoat every few years to keep the court fresh.

- Professional Standards: ISO certifies acrylic flooring to meet global standards, making it a cost-effective choice for Indian projects.

With long life, vibrant finish and superior playability synthetic acrylic flooring is the choice for modern sports flooring solutions.

Applications of Acrylic Sports Flooring

Synthetic acrylic sports flooring is the most adaptable and widely used surface in India. Its durability, weather resistance and professional play quality makes it suitable for multiple sports.

- Basketball Courts: Acrylic flooring provides good grip, consistent ball bounce and safe movement for fast paced games. Cushion options reduce stress on knees and ankles during practice and tournaments.

- Pickleball Courts: With the sport growing rapidly, acrylic sports flooring makes sure proper pace, slip resistance and clear line markings for smooth rallies and safe play.

- Tennis Courts: Acrylic flooring offers medium to fast pace, UV resistance and all-weather durability. It’s a preferred choice for academies and community tennis courts facilities.

- Badminton Courts (Outdoor): For outdoor badminton court flooring setup, acrylic flooring provides non-slip texture and long-lasting performance, unlike cement floors which wears out quickly.

Acrylic flooring delivers professional-level sports flooring that is cost-effective, colorful, and easy to maintain, making it the preferred solution for modern sports infrastructure in India.

Technical Composition of Synthetic Acrylic Flooring Materials

Synthetic acrylic sports flooring is made of materials that work together to give a safe, durable and high-performance surface.

- Acrylic Resurface: The binding agents that form the smooth and durable film of the surface.

- Silica Sand: Added in layers to give texture, grip and slip resistance for sports like basketball, pickleball, tennis court flooring and badminton.

- Color Coat: High quality color coats that give vibrant finishes and UV resistance to Indian weather.

- Cushion Coat (optional): Elastomeric layers used in cushion acrylic flooring to absorb impact and reduce stress on player’s joints.

- Line Marking Paints: Acrylic based paints applied with precision to mark basketball, pickleball, tennis and badminton court boundaries.

This composition makes acrylic flooring perfect for professional and recreational sports flooring projects, safety, performance and low maintenance.

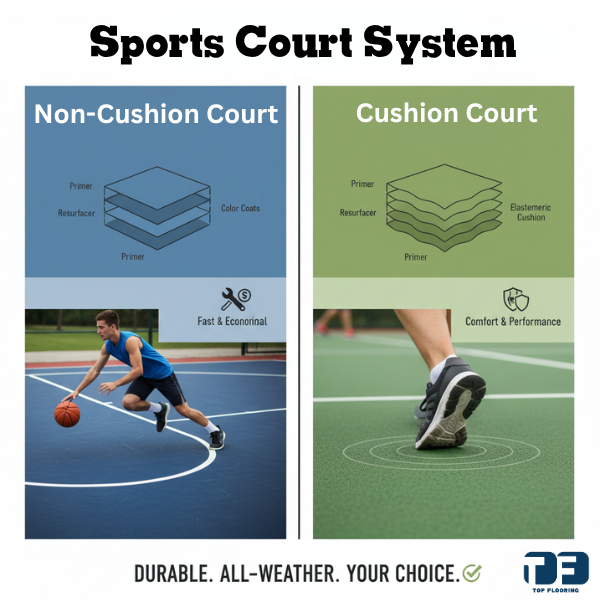

Layer Systems Explained: Non-Cushion vs Cushion Courts

Synthetic acrylic sports flooring can be installed in two main systems – non-cushion courts and cushion courts. The choice depends on budget, comfort, and type of play.

Non-Cushion Courts

- Made with primer, resurface, and acrylic color coats.

- Provide a fast, hard-playing surface ideal for competitive basketball, pickleball, tennis, and outdoor badminton.

- Cost-effective and easy to maintain.

- Suitable for schools, housing societies, and community courts where high-speed play is preferred.

Cushion Courts

- Built with additional elastomeric cushion layers under the acrylic color coats.

- Offer shock absorption and player comfort, reducing stress on knees and joints during long training or matches.

- Popular for academies, clubs, and high-performance facilities.

- Slightly higher in cost but delivers a premium playing experience.

Both systems deliver durable, weather-resistant acrylic flooring. Non-cushion is chosen for speed and economy, while cushion courts are preferred for comfort and professional-level sports flooring.

Base Construction & Civil Requirements for Indian Projects

Synthetic acrylic sports flooring performance depends on the base. A good civil foundation makes sure durability, drainage and playability.

Concrete or Asphalt Base

- Most common in India is M25+ grade concrete with reinforcement.

- Asphalt can be used but not common in Indian projects.

Key Civil Requirements

- Slope: 1:100 minimum for smooth water drainage.

- Surface Finish: Smooth, level and free from cracks or undulations.

- Curing: Concrete base must cure for at least 28 days before applying acrylic flooring.

- Moisture Control: Proper drainage channels must be in place to stop water seepage.

- Joint Treatment: Expansion and construction joints should be sealed.

Why It Matters

Without proper base preparation even, the best sports flooring fails. Slope, flatness and curing are the foundation for a long lasting synthetic acrylic flooring installation in basketball, pickleball, tennis and badminton courts.

Step-by-Step Installation Process

Building a professional synthetic acrylic sports flooring system starts with the right base and correct layering. Process varies for concrete bases and asphalt bases.

1. Concrete and Asphalt Base Preparation

- Concrete Base: M25+ concrete with 1:100 slope for drainage. Cure for at least 28 days. Repair cracks, seal joints and grind uneven areas.

- Asphalt Base: Dense bituminous macadam (DBM) with proper compaction and smooth finish. Check for slope and flatness (3 mm tolerance under 3 m straightedge).

2. Primer (Only for Concrete Base)

- Apply Concrete Primer to improve durability between concrete base and subsequent acrylic layers.

- Note: Asphalt bases do not require primer.

3. Acrylic Resurface

- Apply Acrylic Resurface mixed with Silica Sand.

- This layer closes base ability to soak up, smooths the surface and provides the right texture for the next coats.

4. Cushion Coats (Optional)

- Apply Cushion Coat in 2-5 layers, depending on the required comfort and shock absorption.

- Recommended for professional basketball and pickleball courts where long hours of play demand reduced joint impact.

5. Color Coats

- Apply 2-3 layers of Color Coat for durability, UV protection and slip resistance.

- Multiple color options available for basketball, pickleball, tennis and badminton layouts.

6. Line Marking

- Use Line Marking Paint for precise boundaries.

- Masking tape makes sure sharp, accurate edges for each sport.

7. Curing & Handover

- 48-72 hours curing depending on the weather.

- Inspect bounce, grip, drainage and finish before opening for play.

International Benchmarks in Sports Flooring

Today Indian sports flooring in the form of synthetic acrylic sports flooring now matches the high standards set by the best in the world. The quality of our materials is on with leading brands like Laykold and California Sports Surfaces. However, our flooring systems are tweaked to suit the Indian climate and to meet the unique requirements of each project they’re built for.

Our flooring systems are made in an ISO-certified facility and are subject to strict quality control. This means that we’re able to deliver the same high-quality sports flooring used by pros all over the world making them perfect for professional level basketball, pickleball, tennis and badminton courts in India.

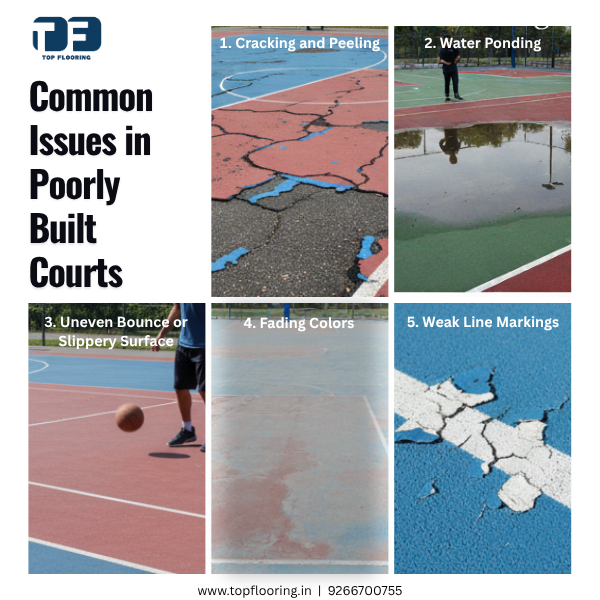

Common Issues in Poorly Built Courts & How to Avoid Them

When you’re using sports flooring, even the best grade of synthetic acrylic sports flooring in the world don’t last long if it’s been installed badly. Bad workmanship or ignoring the technical requirements of the installation can all end up reducing the lifespan and performance of your court.

1. Cracking and Peeling

- Cause: The concrete base just wasn’t given long enough to cure, and then the joints weren’t sealed properly, and on top of that it’s easy to apply too many coats when using a clear finish.

- Solution: Take the time to allow the concrete to properly dry we’re talking 4 weeks here. And use a concrete primer to protect it, also make sure to seal the joints properly right off the bat.

2. Water Ponding

- Cause: You didn’t quite get the slope right or the drainage design was rubbish.

- Solution: Always make sure the base is sloped at a rate of 1:100 and that you install side drains to help get rid of any water that does collect.

3. Uneven Bounce or Slippery Surface

- Cause: You skipped applying the resurface layer, or you’ve mixed up some of the sand, or you’re spraying the topcoat without any care for even coverage.

- Solution: Take your time and make sure to apply the resurface layer with some silica sand mixed in.

4. Fading Colors

- Cause: You’ve gone with cheap colors, or you haven’t applied enough topcoats.

- Solution: Apply a couple of coats of topcoat with some high quality, UV resistant color coats to get a finish that really lasts.

5. Weak Line Markings

- Cause: You’ve gone with ordinary paint instead of the special acrylic line marking paint.

- Solution: Get yourself some proper line marking paint to get some nice, long-lasting lines that will keep people coming back to your court.

Conclusion

The explosion of basketball, pickleball, tennis, and badminton in India has created a huge demand for reliable, high-quality sports flooring. Among all the options, synthetic acrylic sports flooring stands out as the best choice. It delivers extreme durability, ensures a smooth and consistent ball response, and performs well in all weather conditions.

When you lay out the right base, apply a proper concrete primer, and add layers of acrylic resurfacer, cushion coat, color coat, silica sand, and line markings, you create a court that meets international standards. Indian manufacturers now produce ISO-certified acrylic flooring systems that match leading brands like Laykold and California Sports Surfaces, while tailoring them to suit the Indian climate and budget.

Frequently Asked Questions

A multi-layer flooring system made with acrylic resins, silica sand and color coats applied over concrete or asphalt to create safe, durable and weather resistant sports courts.

Basketball, pickleball, tennis and badminton courts and multi-sport areas.

Non cushion courts: Harder, faster and more cost effective.

Cushion courts: Have cushion coats that absorb shock and reduce stress on joints.

With proper maintenance synthetic acrylic sports flooring lasts 5-7 years with recoating every 3-5 years.

Yes, for concrete bases (using concrete primer).

Not for asphalt bases where primer is not needed.

Minor cracks, peeling, water ponding, fading colors and weak line markings mostly caused by poor base preparation or low-quality application.

Cement floors crack, fade and offer poor bounce while acrylic flooring makes sure consistent performance, vibrant colors and long-term durability.

Yes, high quality systems in India are made to ISO standards making sure durability and safety equal to international benchmarks like Laykold and California Sports Surfaces.