Designing, constructing, or resurfacing a tennis court is a long-term investment. When done correctly, the court can last 10–15 years with consistent performance. But when a tennis court is installed incorrectly starts showing cracks, bubbles, drainage issues, colour fading, and surface failure within months. Most of these problems happen because of a few common tennis court flooring mistakes made during planning, tennis court construction, material selection, or installation.

With over 14 years of hands-on industry experience and thousands of completed acrylic sports courts, Top Flooring has seen exactly why certain courts fail and how to avoid those mistakes from the beginning. This blog uses Expertise, Experience, Authoritativeness, and Trustworthiness — to give you a proven guide on avoiding costly mistakes, especially if you plan to build a tennis court, resurface an older court, or hire professional tennis court builders.

Why You Need to Avoid Mistakes in Tennis Court Construction

A tennis court is more than paint on a concrete base. It’s a complete engineering system comprising base slab, slope, drainage, surface coatings and long term maintenance. Every small mistake in these areas adds up to:

- Future repairs: A small tennis court construction or material mistake can turn into major structural damage over time. This means it requires more frequent and costly repairs which reduces the long term value of the tennis court.

- Resurfacing frequency: Courts with poor base preparation or bad acrylic application wear out faster. This means you have to resurface the tennis court more often than the recommended 5-7 year cycle.

- Lifetime maintenance cost: Low quality tennis flooring materials and wrong installation means more cleaning, patching and repair costs. These added costs will exceed the original construction budget of the tennis court.

- Early cracking: Weak concrete, bad slope and inadequate compaction leads to early surface cracks. Once cracks appear they spread fast and compromise the entire court structure.

- Poor ball bounce: Uneven coatings, and surface irregularities affect the ball response. This means unpredictable bounce quality and the court is not suitable for professional or academy level play.

- Water pooling: Bad slope or drainage means water accumulation after rain. Standing water weakens coatings, forms algae and accelerates cracking and surface deterioration.

- Slippery surfaces: Low quality acrylic flooring or wrong texture mix reduces surface traction. Slippery courts means more injuries and more frequent cleaning and recoating.

- Colour fading: Using non-UV resistant tennis court materials gets rapid colour loss in Indian heat and sun. Fading not only affects the court’s appearance but also means coating breakdown.

Wrong Tennis Court Base Construction and Slope

Most tennis courts start having problems right from the beginning because the tennis court base is not built properly. The issue is rarely with the acrylic coating, the real problem is the weak or badly made foundation underneath. If the base is not done right, you’ll end up spending a lot of money later on for major repairs.

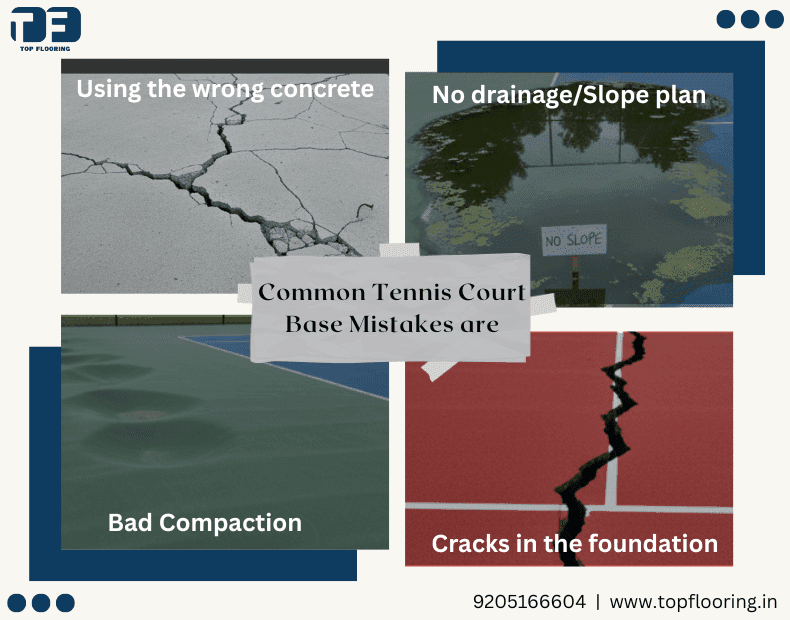

Common Base Mistakes are:

- Using the wrong concrete: If you’re using a low strength concrete it starts to see cracks and structural instability – and that makes a surface that can’t handle heavy use or weather stress.

- No slope: A completely flat surface is bad for drainage. Water will collect, algae will grow, and the acrylic surface won’t last long because the moisture gets trapped.

- No drainage plan: Many courts are built without proper drainage. When water can’t flow out, it starts getting problems like small water puddles and moisture seeping onto the surface.

- Bad Compaction: If the sub-base isn’t packed tightly, the ground will settle unevenly. This causes dips, cracks and an uneven surface that makes the court feel bumpy and unstable.

- Cracks in the foundation slab are a big problem: If the foundation has cracks, those cracks will eventually show up on the acrylic surface too. This leads to “reflective cracking,” which means the court will keep breaking again and again. You’ll need frequent repairs, and the court’s lifespan will become much shorter.

Building a Tennis Court Base The Right Way

- Use a high-strength concrete: You need at least an M20 or M25 concrete grade for a tennis court. Anything weaker will cause problems because the foundation won’t be strong enough to handle heavy play or harsh weather.

- 1:100 slope – it’s not that hard: A proper slope is very important for drainage. If the court is sloped correctly, water will flow out easily, and you won’t have issues like puddles, seepage or any other drainage problems.

- Add some good drainage outlets: This is basic — if water can flow out quickly, your acrylic layers will stay safe and won’t bubble or peel off.

- Compact that sub-base: Good compaction is crucial for a strong, long-lasting court. If you skip this, the ground will settle unevenly and cause cracks, dips and bumps later.

- Don’t cut corners: Skipping proper base work may save time now, but it will cost you much more in the future. Poor preparation leads to costly repairs, resurfacing and early failure of the court.

Using Wrong or Low-Quality Tennis Court Materials

Low-grade or diluted materials fail to withstand India’s harsh climate, which includes extreme heat, humidity, and heavy monsoons. This leads to early surface deterioration, costly repairs, and frequent resurfacing.

- Fading within months: Low-quality pigments lose colour quickly under UV exposure, making the court look old and patchy in a short time. This reduces both aesthetics and long-term value.

- Peeling and bubble: Weak adhesive strength and incorrect formulations cause air pockets and delamination. These issues worsen with heat expansion, leaving the court unsafe and uneven.

- Slippery surface: Cheap fillers and low-grip coatings fail to provide the required traction. This increases the risk of skidding, injuries, and poor playability during humid or damp conditions.

- Uneven colour: Non-uniform blending and inconsistent paint quality lead to patchy or streaky colour across the court. This makes the surface look unprofessional and affects visibility lines.

- Loss of grip: Inferior texture additives wear off faster, reducing the ball’s bounce control and player traction. This compromises performance and requires early re-coating.

- Wear and tear: Poor tennis court materials break down quickly under heat, rain, and regular play. This shortens the tennis court resurfacing cycle and increases overall maintenance costs.

Always choose high-quality synthetic tennis court material, ITF-grade acrylic systems, and premium tennis court resurfacing materials engineered for UV stability and long-term durability. Top Flooring’s advanced acrylic systems are designed specifically for the Indian climate, ensuring superior grip, colour consistency, and long-lasting weather resistance.

Skipping Proper Surface Preparation

Many tennis courts fail early because the surface was not prepared correctly before coating. Problems that seem small during installation eventually turn into major repairs and resurfacing expenses.

Common mistakes include:

- Applying acrylic over dust, oil, or dirt: This prevents proper adhesion and causes peeling, bubbles, and texture failure within months, especially under heat and moisture.

- Skipping primer: Without primer, the acrylic system cannot bond with the concrete base, resulting in weak layers that break down quickly.

- Not repairing cracks: Cracks expand with heat, moisture, and foot traffic, eventually damaging the acrylic coating and requiring full resurfacing.

- Applying coatings on wet surface: Moisture trapped under the surface causes bubbles, blisters, and delamination, ruining the finish and shortening the court’s lifespan.

- Not fixing low spots: These small dips hold water, which makes the court slippery, encourages algae to grow, and causes uneven colour. Over time, this speeds up the damage and wear of the surface.

- Poor crack-routing technique: Incorrect crack treatment causes refilling failure, leading cracks to reappear through the acrylic layers soon after installation.

These mistakes drastically increase future needs for tennis court repair materials and costly resurfacing.

Correct Tennis Court Surface Preparation includes:

- Mechanical cleaning: High-pressure washing or machine scrubbing removes dust, residue, and contaminants, ensuring proper bonding of each acrylic layer.

- Moisture testing: This identifies hidden dampness within the slab, preventing blistering and surface failure caused by trapped moisture.

- Crack repair: Routing, filling, and sealing cracks keeps the base structurally sound and prevents reflective cracking through the acrylic system.

- Patch leveling: Uneven areas are filled with patch binders to create a perfectly flat play surface and avoid water stagnation.

- Applying acrylic primer: Primer creates a strong bond between the concrete and resurfacer layers, increasing durability and surface strength.

- Using professional resurfacer mixes: Engineered resurfacers build a uniform base layer, improving coating adhesion, colour consistency, and long-term performance.

Skipping any of these steps leads to long-term damage, early resurfacing, and higher repair costs.

Incorrect Acrylic Application & Layering

Applying acrylic sports coatings is a technical process that requires precision, experience, and the right tools. When the application is handled incorrectly, the tennis court surface quality deteriorates almost immediately, leading to long-term performance issues.

Typical Tennis Court Layer Application Mistakes

- Applying thick coats: Thick acrylic layers trap moisture inside and prevent proper curing, leading to soft spots, bubbles, and peeling within a short time. Each coat must be thin and evenly spread to achieve a durable finish.

- Wrong squeegee technique: Using the wrong squeegee angle or pressure creates inconsistent texture and uneven thickness across the court. This affects ball bounce, grip quality, and overall playing performance.

- Rushing the process: If installers work too fast, the layers don’t dry, settle, or stick properly. This causes weak bonding and early damage, which means you’ll end up paying for repairs or resurfacing much sooner.

- Not letting layers cure: Every acrylic coat needs proper drying time to build strength. Incomplete curing leads to soft, sticky, or patchy surfaces that deteriorate quickly under player movement.

- Mixing materials incorrectly: Incorrect ratios of acrylic, filler, or water weaken the coating structure. This causes colour inconsistency, poor texture formation, and reduced lifespan of the court.

- Working in extreme weather: Applying acrylic flooring during high temperatures, humidity, rain, or early morning dew disrupts the curing process. This leads to blisters, pinholes, and surface defects that require tennis court renovations later.

Correct Tennis Court Layering Application Approach

- Apply 5–8 layers depending on the system: A proper acrylic system includes resurfacer, colour coats, and line marking layers — each added gradually to build a strong and consistent surface profile.

- Maintain thin, even coats: Thin coats ensure uniform colour, perfect texture, and strong adhesion between layers, preventing peeling or premature coating failure.

- Allow full drying time: Each coat must cure completely before the next layer is applied to avoid soft patches and ensure long-lasting durability.

- Avoid heat or humid conditions: Ideal application temperatures allow the acrylic surface to cure uniformly. This prevents blistering and maintains the true performance characteristics of the court.

- Professional applicators: Experienced technicians understand the exact mix ratios, squeegee technique, and environmental conditions needed to deliver a smooth, consistent, ITF-style surface.

Incorrect Measurements & Line Marking Problems

Lots of contractors end up creating tennis court measurements that are all wrong or line markings that are completely off.

These Mistakes Can Cause:

Incorrect measurements and line marking are common, yet important errors in tennis court construction. A lot of contractors who are new to the game don’t always follow the ITF dimensions as tightly as they should, which means you end up with baselines that are way off, service boxes that are the wrong size, uneven line widths or lines that just don’t straight up go where they’re supposed to. These kinds of errors mess with the gameplay real bad. They mess with player movement, create spaces that are all uneven, and totally change up the dynamics of the rally.

If the court lines are not marked properly, the court doesn’t just look bad — it looks uneven and unfinished. And for schools, academies, clubs, or competitive venues, it’s not only about appearance. Tennis is a precise sport, so accurate measurements and perfect line marking are absolutely essential. Getting the lines right makes the difference between fair play, correct ball bounce, and a clean, professional court that meets official standards. Proper markings are a must if you want a tournament-ready tennis court. Accurate dimensions are a must when you’re building a tennis court, especially if you’re working with schools, or clubs.

Ignoring Long-Term Maintenance of Tennis Court

Even the best court requires routine cleaning and basic care to preserve its performance, grip, and structural integrity. When regular maintenance is skipped, the surface begins to degrade much faster than expected. This not only affects gameplay but also leads to expensive repairs and early resurfacing needs.

Ignoring maintenance leads to:

- Dust accumulation: Dust settles quickly on outdoor courts, especially in India’s dry and windy regions. If not removed regularly, it forms a thin powdery layer that reduces surface grip. This makes the court slippery and uncomfortable for players while increasing wear on the acrylic coating.

- Slippery algae: Moisture, shade, and poor drainage create ideal conditions for algae growth on the surface. Algae make the court dangerously slippery and compromise player safety. Over time, they also penetrate the coating and cause discoloration and soft patches.

- Moss formation: Moss often grows in corners, edges, and areas with stagnant water. Once it spreads, it traps moisture and softens the acrylic layers beneath. This leads to premature surface deterioration and increases the frequency of cleaning and resurfacing.

- Local cracks: Small cracks may seem harmless initially, but they grow quickly when left unattended. Temperature changes, moisture, and continued play widen these cracks and can damage the concrete base. Repairing early prevents the need for major tennis court resurfacing near me services.

- Early wear: Without cleaning and early repairs, courts lose texture, colour, and grip faster. Dirt, shoe friction, and weather exposure accelerate the wear process. This reduces the overall life of the sports surface and increases long-term maintenance expenses.

- Poor traction: Accumulated dirt, moss, and faded coatings significantly reduce traction. Poor traction affects player performance and increases the risk of slips and injuries. Maintaining proper grip ensures safer play and extends the life of the acrylic layers.

When these issues build up, owners end up needing frequent resurfacing, raising overall costs and leading to long downtime.

Basic Tennis Court Maintenance checklist

- Clean monthly: A simple monthly cleaning removes dust, debris, and surface contaminants. Consistent cleaning preserves the court’s grip and prevents dirt from settling deep into the acrylic texture. It also reduces long-term abrasion caused by friction during play.

- Wash off mud and dust: Mud splashes and accumulated, dust degrades colour and creates slippery patches. Washing the tennis court using mild detergent and water restores the surface texture. It also prevents dirt buildup, which can speed up wear and dull the court’s appearance.

- Fix minor cracks early: Treating hairline cracks early prevents them from expanding into structural damage. Quick repairs protect the base slab from moisture penetration. This saves significant cost to build a tennis court in the long run by delaying major renovations.

- Repaint lines when faded: Court lines fade with sun exposure and regular play, affecting visibility and gameplay. Refreshing line markings maintain professional playability standards. It also restores the overall aesthetics of the court.

- Inspect drainage: Clogged drains or improper water flow lead to puddles and algae growth. Regular drainage checks keep water moving away from the surface. This prevents moisture-related issues like peeling, bubbles, and soft spots.

- Resurface every 5–7 years: Acrylic tennis courts need resurfacing depending on usage, climate, and maintenance. Timely resurfacing renews colour, texture, and performance. It also extends the lifespan of the base structure and delays major reconstruction costs.

Proper care significantly increases the life of your tennis court investment. By consistently following this maintenance routine, you reduce the long-term cost to build a tennis court, avoid premature resurfacing, and ensure a smooth, safe, and high-performance playing experience for years.

Choosing Wrong Contractors or Low-Experience Builders

Choosing the wrong contractor — especially someone who has little or no experience in tennis court construction — is one of the biggest and most expensive mistakes you can make. A tennis court is a technical project that requires skill and precision. The base preparation, drainage, slope, acrylic layers, and line markings all need to be done correctly.

If the contractor doesn’t know what they’re doing, everything can go wrong: the base may be laid unevenly, the acrylic mix might be watered down or mixed incorrectly, the colours may look patchy, cracks can appear much earlier than expected, and water may not drain because the slope isn’t set right. All of this leads to major problems and costly repairs later.

And that’s not all — if the tennis court measurements are wrong or the acrylic layers don’t stick properly, the surface can start peeling off early. These mistakes are difficult and expensive to fix, and they can reduce the court’s lifespan by years. That’s why it’s so important to hire a reliable tennis court construction company. You need experts who understand technical details, know how to work in different climate conditions, and can build a court that lasts long without constant repairs.

Not Understanding Total Cost & Long-Term Budgeting of Tennis Court

Many people only take a look at the initial tennis court construction cost, but the total budget includes long-term care. A tennis court is a significant investment that over time demands ongoing attention to keep it safe, durable, and still performing like it should. Ignoring future costs down the line can catch you off guard with unexpected expenses, faster surface damage and a reduced court lifespan.

Long-Term Expenses People Often Ignore

- Maintenance: Regular maintenance is essential for preventing dust buildup, algae, and surface wear. Without routine cleaning and inspection, the court loses grip and becomes unsafe. Long-term maintenance helps extend the life of the acrylic layers and delays major repairs.

- Resurfacing: Every 5–7 years, courts require resurfacing to restore bounce, colour, and traction. This involves adding new acrylic layers, repairing depressions, and refreshing the lines. Budgeting for resurfacing early prevents sudden, large expenses later.

- Repairs: Minor cracks, and surface irregularities appear over time due to weather and usage. Addressing them immediately prevents structural damage and reduces repair costs. Ignoring repairs leads to resurfacing failure and higher future spending.

- Re-coating: The colour layers fade due to UV exposure, rain, and continuous play. Re-coating helps maintain aesthetics, grip, and weather protection. Scheduled re-coating ensures the surface stays vibrant and playable for years.

- Crack Treatment: Cracks naturally develop from slab movement, temperature shifts, and structural stress. Treating them early with proper fillers and binders stops them from expanding. Without timely crack treatment, the court may require expensive reconstruction.

Factors That Determine the Total Cost of Building a Tennis Court

- Base type: Concrete and asphalt bases have different pricing, durability, and preparation requirements. The strength and quality of the base influence long-term repairs and resurfacing cycles. Choosing the right base prevents cracking and drainage failure.

- Acrylic system: Acrylic systems vary between basic and cushioned (5-layer to 9-layer). Higher-quality systems cost more initially but offer better comfort, bounce, and longevity. The right system ensures consistent performance with lower lifetime maintenance.

- Location: Accessibility, soil conditions, climate, and transportation impact overall pricing. Remote locations may require additional logistics and labor. Hot or monsoon-heavy regions demand more durable acrylic formulations.

- Ground condition: Uneven, weak, or moisture-prone soil requires extra preparation and stabilization. Poor ground conditions lead to cracks, depressions, and ongoing repair expenses. Investing in proper base preparation saves future structural costs.

- Drainage: Efficient drainage prevents water pooling, birdbaths, and moisture-related surface failure. Adding proper slope, channels, and drainage lines affects initial cost but avoids long-term resurfacing issues. Good drainage equals longer court life.

- Cushioning layers: Adding cushion layers improves comfort and reduces player impact, especially for academies and clubs. These layers increase initial cost but enhance user experience and reduce surface fatigue. Cushion-courts also absorb wear better over time.

Keeping long-term care in mind helps you avoid sudden repair bills and fully understand the true price to build a tennis court. Proper planning ensures your court remains durable, safe, and cost-efficient throughout its lifespan.

When to Hire Tennis Court Builders

If you’re searching for tennis court installation near me, or a reliable tennis court manufacturer, make sure the team you choose offers these essentials:

- Proven experience: Work only with contractors who have a strong portfolio of completed tennis courts and years of field expertise, ensuring they understand every layer of the construction process.

- Climate-specific products: Tennis court materials must be engineered for India’s extreme conditions such as high heat, UV radiation, humidity, and heavy monsoon rainfall.

- Skilled applicators: Acrylic systems require trained applicators who understand squeegee angles, layer thickness, cure times, and texture control.

- Accurate mixing ratios: Acrylic materials must be mixed precisely as per technical guidelines to maintain strength, flexibility, and bonding.

- ITF-style systems: Professionally engineered systems aligned with ITF standards ensure correct pace, ball rebound, and uniform playability.

- Long-term support: The right tennis court flooring company should offer guidance on maintenance, repairs, resurfacing cycles, and future upgrades.

Top Flooring specializes in acrylic tennis court construction, resurfacing, installation, and professional material supply across India. With thousands of completed courts, we deliver engineered systems designed for extreme Indian climates, ensuring durability, grip, and long-term performance even in high-traffic environments.

Conclusion

Avoiding these tennis court flooring mistakes is not just about saving money — it is about ensuring that your court performs consistently, supports safe play, and withstands India’s harsh weather conditions year after year. A tennis court is a long-term asset, and every decision taken during planning, tennis hard court construction, material selection, installation, and maintenance directly affects its lifespan.

Top Flooring, one of India’s experienced manufacturers and suppliers provides engineered acrylic systems, premium synthetic tennis court material, and tested tennis court resurfacing materials specially designed to handle extreme heat, monsoon moisture, and heavy footfall. From consultation to tennis hard court construction, surface repairs, installation guidance, and complete resurfacing solutions, Top Flooring offers end-to-end support across India.

Frequently Asked Questions

Base construction, acrylic layers, fencing, lighting, and drainage all increases the cost to build a tennis court.

You should resurface tennis court every 4–7 years depending on usage and maintenance.

Early cracking usually happens because of poor sub-base compaction, wrong concrete grade, or no control joints. These structural issues push cracks upward into the acrylic surface.

Yes. A tennis court must have a 1:100 slope for proper drainage. A flat court causes water pooling, algae, and surface peeling shortening the court’s lifespan.

Peeling happens when layers were applied too fast, the base was dusty, or the acrylic mix was diluted. Proper cleaning, curing time, and correct ratios are important.