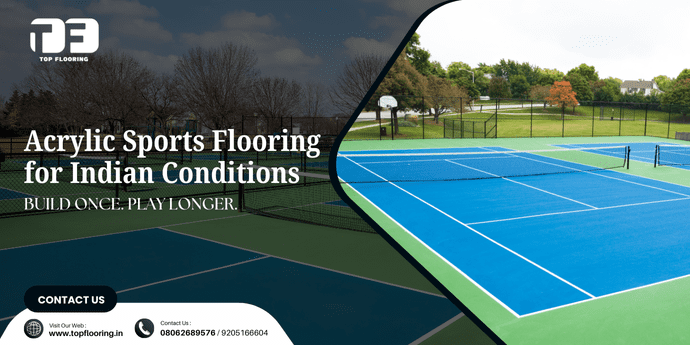

Walk across an outdoor sports court in many parts of India, and you’ll often notice early signs of surface failure in the acrylic sports flooring. Colours fade within just a few years, once-grippy areas start feeling smooth and slippery, and small cracks slowly spread across the surface like a spider’s web. In some cases, sections of the acrylic sports flooring system even begin to peel away from the concrete base despite the court looking like it should still have years of life left.

The usual excuses you hear for this sort of thing – “poor installation” and “lack of maintenance” – just don’t cut it. Proper workmanship still matters, but experience across Indian cities shows that installation is rarely the main issue. The real problem lies in how the system is designed and whether it can handle local climate conditions. The actual lifespan of an acrylic sports flooring system depends more on its design and how well it handles environmental conditions than on how it’s applied.

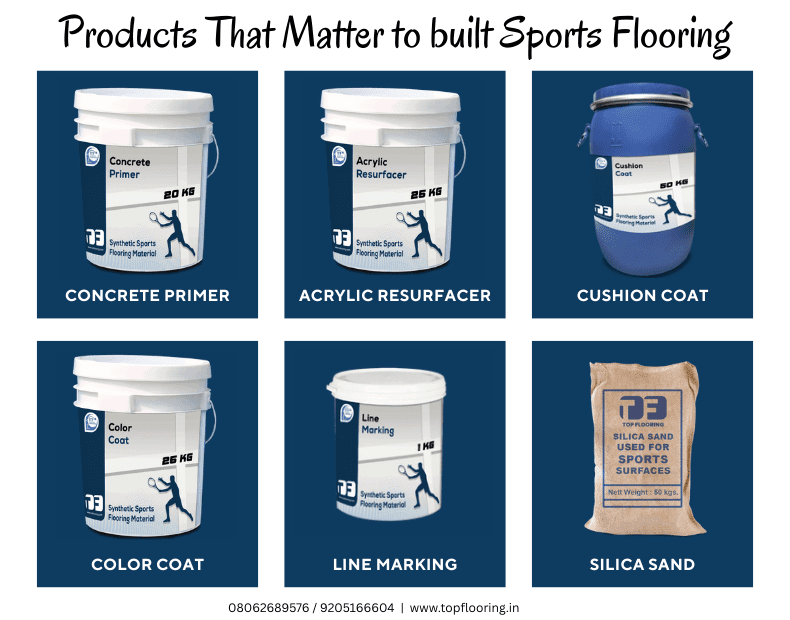

Understanding an Acrylic Sports Flooring System

One of the most common misconceptions in sports infrastructure development is to think of acrylic flooring as just a single layer of material. A well-designed synthetic acrylic sports floor uses several carefully applied layers, and getting these layers right takes you halfway to building a high-quality sports floor. Here are some of the key products:

Primer

Primer is basically the foundation of the whole system. Its main job is to make sure the synthetic acrylic sports layers stick to the concrete base really well. In India’s damp conditions, a proper primer is essential to prevent peeling and blistering on concrete surfaces.

Resurfacer

Resurfacer layers smooth bumps, fill surface gaps, and create a strong, even base for the court. They spread stress evenly, preventing it from reaching and damaging the upper layers.

Cushion Coats

The cushion coats are what make the floor feel comfortable to play on. They absorb impact, reduce stress on the body, and help the ball bounce consistently. But if done poorly, the floor becomes unstable, loses shape over time, and wears out quickly.

Colour Coats

Colour coats are not just about looking nice – although let’s be honest, they do that too. They also protect the other layers from the sun, stop them from getting too hot in the sun, and help to keep the floor looking good.

Line Marking

Line marking paint needs to be flexible, it needs to stick to the floor really well, and it needs to stay visible even when the floor is moving up and down. If the paint is not up to the job, you end up with cracks and fading after a short time.

In the Indian climate, the key to a long-lasting floor is getting all these layers working together as a system. It’s not about any one of them on its own – it’s about how they all fit together.

Climate Compatibility: The Biggest Factor in India

When talking about sports court flooring in India, climate compatibility is the one thing that makes all the difference in how long a surface will last.

High Heat

In the peak summer, the surface temperature of outdoor courts can easily outstrip the air temperature. Acrylic binders that can’t handle the heat stress just end up rock hard, and over time, this causes them to lose their elasticity and start cracking.

Intense UV Exposure

India faces intense direct sunlight for most of the year, making it a major challenge for sports flooring durability. Prolonged UV exposure is a guaranteed way to break down low-quality binders and pigments, making surfaces fade, powdery and chalky.

Dust and Abrasion

You think dust is just a cleanliness thing, but it’s actually a major stress factor. Every time you walk on it, dust is wearing down your surface, reducing the grip and texture & it’s not just dirt, either, it’s tiny particles acting like sandpaper underfoot.

Monsoon Moisture and Humidity

Monsoon is not just about heavy rain; it’s about prolonged moisture that’s the real killer. And then there is the humidity, too; it screws with the curing process and weakens the bonds between layers. An effective sports flooring system for the Indian climate must resist all these forces at the same time.

Role of UV Stability & Heat Resistance

UV stability and heat resistance play a crucial role in how long a surface lasts, yet people often overlook them when choosing a material.

- Colour Retention– Poor-quality pigments fade quickly in sunlight, reducing colour clarity and on-court visibility.

- Binder Flexibility– Acrylic binders must flex with heat; otherwise, expansion and contraction cause surface cracks.

- Texture Integrity– Excessive heat softens the binder, causing texture loss and creating an uneven, slippery surface.

Top Flooring designs its outdoor acrylic court flooring materials with UV-stable components that withstand India’s extreme heat, rigorously testing them to ensure long-lasting performance and consistent play.

Texture Design & Abrasion Resistance

People tend to just think about texture from a safety angle, but when you look at it from a durability perspective, it really does start to play a much bigger role. In the Indian climate, your floors have to be able to put up with a lot, including:

- Dust just settles on the surface all the time

- Sand is getting rubbed into the surface from people’s shoes

- Super high foot traffic in schools, academies and public courts

Top Flooring has texture systems that can withstand the rough stuff. They’re designed to give you a good grip and then, when they do wear down, to do so in a way that keeps the surface stable even when loads of people are using it.

Bonding Strength & Monsoon Performance

One of the biggest problems with acrylic flooring in India is how it deals with the monsoon season. The thing is, monsoon weather exposes a lot of weaknesses in the adhesion. When all that rain comes down, it makes a real mess of things:

- It stops the curing process from getting to work properly

- The layers underneath can begin to separate

- long-term worry is delamination – where the whole thing starts to peel away

Most imported or generic acrylic materials are designed for dry climates with controlled curing conditions, so they struggle to perform well in Indian weather, where concrete often stays damp long after rainfall.

Resurfacing & Long-Term Maintenance

A good, long-lasting acrylic flooring system is one that doesn’t just resist wear and tear but also ages in a way that you can predict. Well-designed systems – and we’re talking about systems, not just individual components have some key qualities that really help them last the distance:

- They take resurfacing in their stride, without needing any invasive prep work to get back to where they were

- The old and new layers seamlessly work together because they are designed that way.

- They reduce maintenance costs and minimise downtime because they’re built to perform.

Top Flooring takes a system-based approach to resurfacing, making the job more efficient while preserving everything that made the court perform well in the first place.

Why Top Flooring Systems Last Longer in India

As a sports flooring manufacturer in India with a long history, Top Flooring keeps pushing the boundaries of what’s possible with our systems, working with real-world conditions all over India.

- We design and test materials to withstand heat, UV, dust, and humidity that quickly damage poorly built sports courts.

- We ensure every system component works together for durability, not just short-term visual appeal.

- Top Flooring delivers long-lasting courts with fewer failures and extended maintenance intervals.

Top Flooring has earned its reputation as one of India’s leading sports flooring companies by building sports surfaces that are both tough and highly reliable. It’s not just us saying this – the ITF has guidelines and best practices on surface performance that basically say the same thing: system-based acrylic flooring is a whole lot better than just slapping on some standalone coating and hoping for the best.

Conclusion

In India, the key to a sports court which can withstand the test of time has nothing to do with magic – it’s really just about creating an acrylic sports flooring system that gets how the local climate works. You need to factor in everything from the materials you’re using to how they’ll interact with each other & the real-world demands of the people actually using it. Heat, intense UV exposure, dust, constant humidity, and monsoon rains stress sports surfaces, and only purpose-designed systems withstand these conditions for years without issues.

Many generic or imported acrylic flooring systems fall short because they aren’t designed for India’s climate or typical concrete conditions. A system engineered for Indian conditions stays flexible, maintains strong bonding, and preserves texture and colour even under extreme weather. That’s why well-designed, India-ready sports flooring systems deliver longer lifespans, fewer issues, and lower long-term maintenance costs.

Frequently Asked Questions

Engineers design it to withstand heat, UV exposure, dust, and heavy monsoon moisture.

They use materials that aren’t formulated to handle the kind of stress Indian conditions create.

Absolutely manufacturers must design it with Indian weather and concrete conditions in mind.

Climate influences curing, adhesion, flexibility, and how quickly the surface wears down.

Yes, a well-designed system with compatible components allows easy resurfacing.