Outdoor sports courts are exposed to constant environmental stress heat waves, heavy rainfall, high humidity, and sudden temperature drops. Over time, these conditions take a toll on the court surface, especially when synthetic acrylic flooring is used outdoors. One of the most common problems seen on courts finished with acrylic sports court flooring is the appearance of bubbles on the surface. These bubbles usually develop when synthetic acrylic coating systems are applied without respecting proper weather conditions and acrylic court curing time, allowing moisture to get trapped beneath the surface.

Bubbles should never be treated as a normal or harmless issue. They are a warning sign of deeper problems related to moisture movement, curing discipline, and surface preparation. If ignored, bubbling can quickly lead to peeling, delamination, uneven ball bounce, and premature surface failure. Understanding why bubbles form and how correct curing prevents them is essential for maintaining long-lasting sports court flooring.

The Issue with Bubbles on Acrylic Sports Courts

Bubbles, also known as blisters, form when air or moisture becomes trapped underneath the acrylic coating layer. As temperatures rise, the trapped moisture converts into vapor, creating pressure that forces the coating to lift upward. This issue is far more common on outdoor courts because changing weather conditions directly affect moisture levels and drying times.

In most cases, the problem is not with the acrylic material itself. Instead, bubbling occurs due to a combination of weather exposure and incorrect curing practices during or after installation.

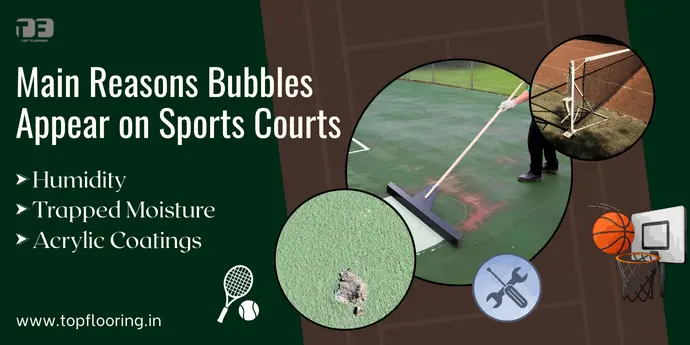

Main Reasons Bubbles Appear on Sports Courts

Excess Moisture Beneath the Court Surface

One of the leading causes of bubbling is excess moisture trapped below the court. Poor drainage allows water to collect under the slab. When the surface heats up, this moisture tries to escape, forming bubbles in the acrylic layer Because Synthetic Acrylic Flooring used on Outdoor.

Applying Acrylic Coatings on Uncured Bases

Concrete and bitumen bases must be completely dry before any synthetic acrylic coating is applied. When coatings are installed on fresh or partially cured bases, moisture remains locked inside the system. The effects may not be immediate, but bubbling often appears weeks or months later.

Incorrect Temperature or Humidity During Application

Weather conditions during application play a critical role in surface performance. High humidity or extreme heat slows drying and prevents proper bonding between layers. Even if the surface looks dry, moisture may still be trapped underneath.

Poor Adhesion Between Acrylic Layers

If one acrylic sports flooring layer is applied before the previous layer has cured properly, adhesion between coats becomes weak. This leads to delamination, where layers separate and form bubbles and soft patches.

Absence of a Vapor Barrier Below the Slab

Without a vapor barrier, ground moisture continuously migrates upward through the concrete. Over time, this moisture pressure causes recurring bubbling, even on resurfaced courts.

Water Seepage from Court Edges

Leaking sprinklers, standing water near edges, or poor side drainage introduce moisture into the base. This increases long-term bubbling risk and weakens the overall court system.

How Proper Court Curing Solves the Problem

Court curing is the most important step in preventing weather-related bubbling. It allows moisture to escape naturally and ensures all layers bond correctly.

Allowing the Base to Cure Fully

Concrete or asphalt should be allowed to cure for 25–30 days before applying acrylic coatings. This ensures internal moisture has disappeared and the base is structurally stable.

Correct Layer-by-Layer Curing

Each acrylic layer must dry completely before the next is applied. Respecting proper acrylic court curing time strengthens inter-layer bonding and prevents moisture from being trapped between coats.

Applying Coatings in Suitable Weather Conditions

Acrylic coatings should only be applied during stable, moderate weather. Avoiding rain, high humidity, and extreme temperatures ensures even drying and long-term surface stability.

Precautions to Avoid Bubbles on Sports Courts

Preventing bubbling requires proper planning and disciplined execution:

- Ensure proper court construction with effective drainage

- Install vapor barriers beneath the slab.

- Allow concrete or asphalt to fully cure before coating.

- Follow manufacturer guidelines for curing and application.

- Apply coatings only in suitable weather conditions.

- Use primers to seal moisture and enhance adhesion.

- Maintain drainage systems regularly.

- Remove standing water and debris from the surface.

Following these precautions significantly reduces the risk of bubbling and surface failure.

Why Choose Top Flooring for Court Curing?

Court curing is not a formality; it determines how long a sports court will last. Top Flooring follows a curing-first approach, focusing on moisture control, weather assessment, and disciplined layer application.

With experience across varied climatic conditions, curing timelines are adapted to site-specific environments. Bubbling issues are addressed at the root cause rather than masked with surface fixes, resulting in durable courts that perform consistently across all seasons.

Conclusion

Weather does not directly damage sports courts; it exposes underlying issues caused by moisture and improper curing. Bubbles on acrylic sports courts clearly indicate that curing steps were rushed or that weather conditions were ignored.

By respecting proper curing timelines, allowing each layer to dry fully, and applying coatings under suitable weather conditions, bubbling can be completely prevented. Correct curing transforms synthetic acrylic flooring into a stable, reliable sports surface that performs year after year.

Frequently Asked Questions

Bubbles form when trapped moisture expands due to temperature and humidity changes.

Yes, high humidity slows drying and traps moisture beneath acrylic coatings.

Yes, rain introduces moisture into the base, which later causes bubbling.

Improper or rushed court curing is the primary cause.

Minor bubbles can be repaired, but widespread bubbling requires resurfacing.